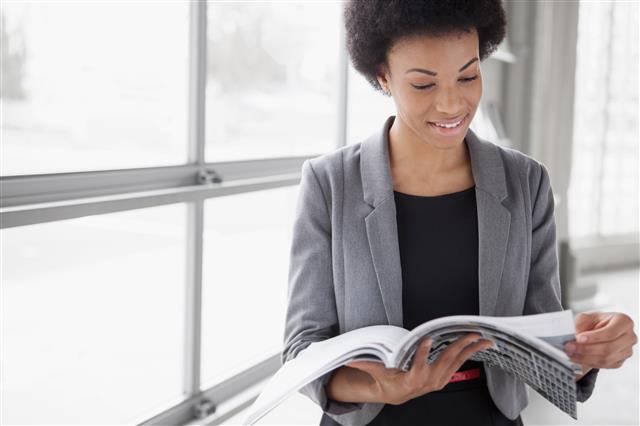

Personalized printing is having a huge impact on the performance of direct mail, but less so on its cousin, the catalog.

Nonetheless, traditional static catalogs are enjoying a revival.

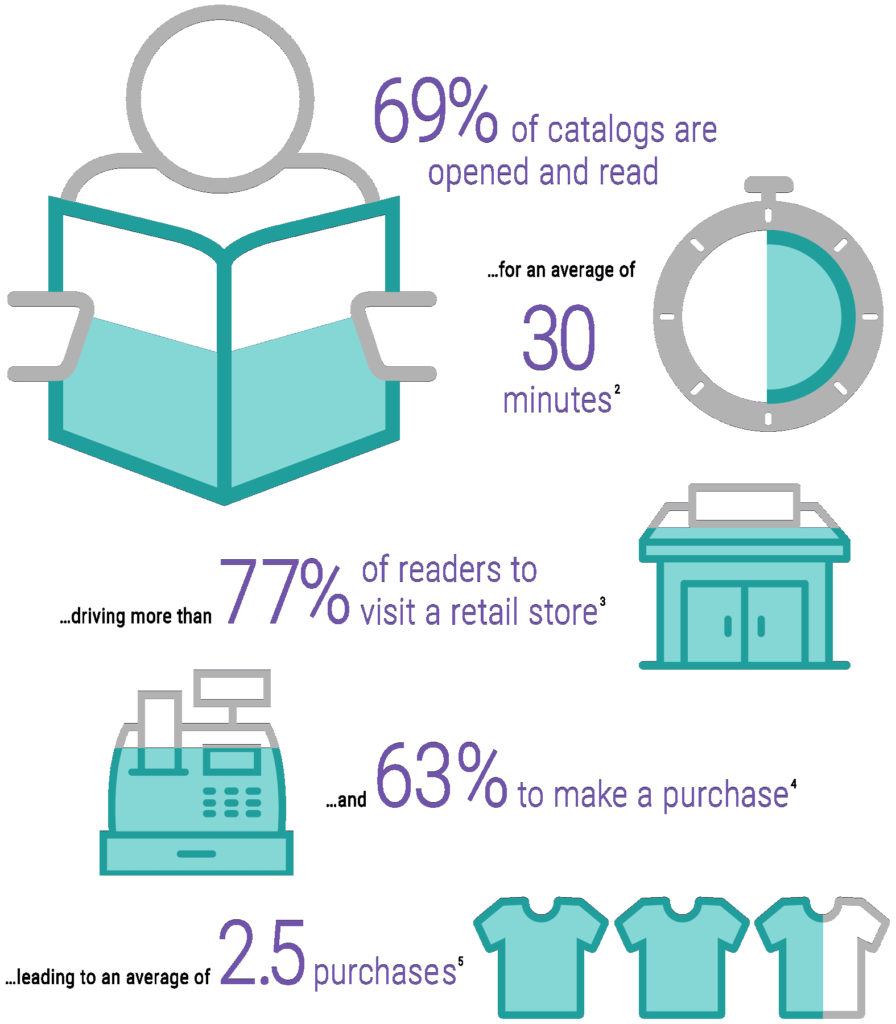

Studies show that 69 percent of consumers consult catalogs before purchases1, 63 percent were influenced by a catalog to make a purchase2 and 77 percent were prompted by a catalog to visit a retail store2. Consumers like browsing through the universe of what is available to better understand their options and perhaps discover something unexpected.

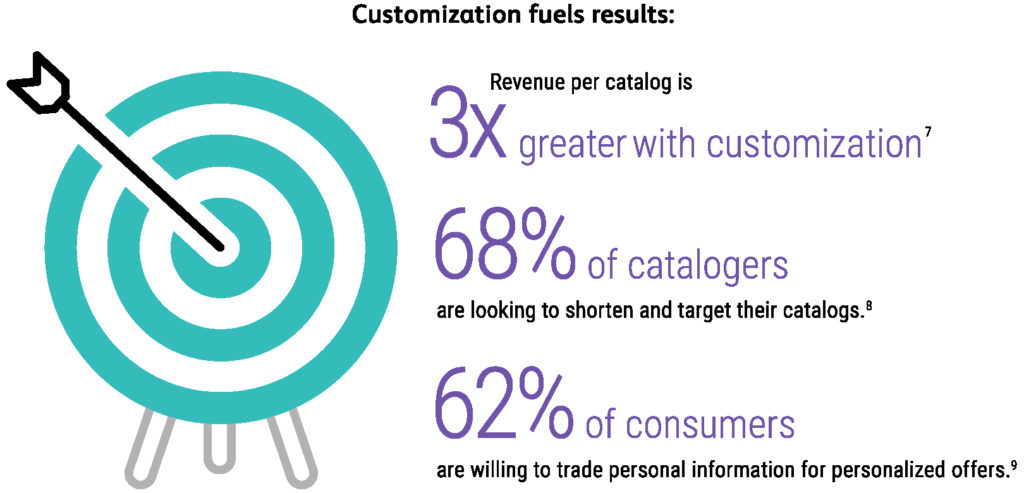

Still, strategically personalized catalogs offer significant promise. Studies show that transactions are three times larger when catalog offers are personalized1. So it’s no surprise that 68 percent of catalogers are seeking personalization solutions1.

Up to now, that quest has been largely unsatisfied. Producing catalogs on the toner-based presses that enable direct mail personalization is too costly for most catalogers. Attempts to mix a little personalization into an otherwise static catalog also have come up short, because they introduce too many cumbersome, manual processes for creating and wedding the static and variable pages. Creating digital versions of the catalog for the Web and mobile devices introduces additional complexities that add to the challenge.

All that may be changing, though.

A new solution, the Xerox Personalized Catalog Solution, brings together several innovations that meet cost, quality and production efficiency targets to make personalized catalogs in print, Web and mobile versions a viable and potentially game-changing option. Those innovations are:

[youtube]http://www.youtube.com/watch?v=foghx3oGrdU[/youtube]

- Automated pre-press workflow

The challenge in pre-press workflow for personalized catalogs is in productively managing three typically discreet workflow processes for digital printing, offset printing and production of digital media.

The Xerox solution’s innovation is the high-degree of automation it brings to pre-press workflow, all orchestrated and managed as a single process by Solimar® ChemistryTM. Chemistry processes orders automatically, orchestrates production by automatically passing assets and instructions to the appropriate workflow components, then tracks the job’s progress.

Several Xerox workflow components bring more automation to keep the work flowing. The personalization campaign is created in XMPie Circle based upon data such as customer buying patterns, and XMPie PersonalEffect generates personalized pages and automatically creates corresponding PURLs and QR codes that enable consumer engagement.

Then Xerox® FreeFlow® Core workflow automation software automatically creates and submits print-ready PDF files, sized and imposed for their target offset and digital presses. Xerox® FreeFlow® Digital Publisher follows up by using the print files to automatically create Web and mobile catalogs properly sized for a variety of devices.

Digitally printed, variable pages that simulate offset quality have typically been too costly for catalog production. The innovation in the Xerox solution is that it achieves brilliant, offset-like image quality with low-cost inkjet printing on the new Xerox® TrivorTM 2400 Inkjet Press. A key contributor is Xerox’s new High Fusion Ink, which also boosts productivity by printing directly on offset-coated stock, without needing treatments, or pre or post coating.

- Automated finishing

Boosting productivity with automated, inline finishing is widespread, but personalized catalogs present a challenge. Namely, the offset and digital pages that must be wed cannot be produced entirely inline.

The Xerox solution meets this challenge by employing the new Muller Martini Presto II Digital Saddle Stitcher, which includes a new collating station. Offset pages are manually loaded into the station and the system takes over, automatically gathering the digitally printed and offset printed pages, and matching them with the right personalized cover.

Other components in the Xerox solution’s Muller Martini Presto II Digital Finishing Line automatically perform other key functions inline, including unwinding and cutting (on a Hunkeler unwinder), folding (on a Heidelberg Variable Stahl Folder), and stitching and trimming (on the Muller Martini Presto II Digital Saddle Stitcher).

The result: personalized catalogs in print, mobile and Web versions produced with near fully automated processes. With these developments printed catalogs will not only experience a revival—they will be reinvented as personal, targeted and relevant revenue-growing engines of customer intimacy.

How can you get started with personalized catalogs? Be sure to download our Catalog eBook, which is full of industry trends, market insights and practical advice to help you capture these opportunities.

Want more? Our Market Segment Series provides key insights and strategies to help you unlock new growth in seven business-boosting application segments – including Direct Mail, Digital Packaging, Photo Publishing and more.

—

- 2015 Xerox-InfoTrends Customer Research

- DMA 2015 Response Rate Report