The inkjet revolution is occurring on multiple fronts.

The inkjet revolution is occurring on multiple fronts.

One wave is bringing inkjet to small and mid-sized printers by scaling the technology with more compact, lower cost cut-sheet and roll-to-cut-sheet presses. These efforts have focused mainly on supporting uncoated stock applications: transactional documents like bills and statements, and direct mail.

Right behind that wave are efforts to accommodate high-quality printing on the traditional coated stocks used in many publishing applications, such as books, catalogs, magazines and higher-end direct mail. Current inkjet systems that accommodate coated stocks require either use of expensive paper or additional production modules incorporated into the print process for treating paper before printing, after printing, or both. These modules add to the already considerable costs and footprint of higher end inkjet devices.

But efforts to enable inkjet printing directly onto commodity offset coated stocks, with no pre- or post-processing, are beginning to bear fruit. Recent demonstrations of Xerox High Fusion Ink at drupa and this week at Graph Expo are giving a glimpse into a technology that is close to entering the marketplace for use on the Xerox® TrivorTM 2400 Inkjet Press.

Inkjet’s Coated-Paper Challenge

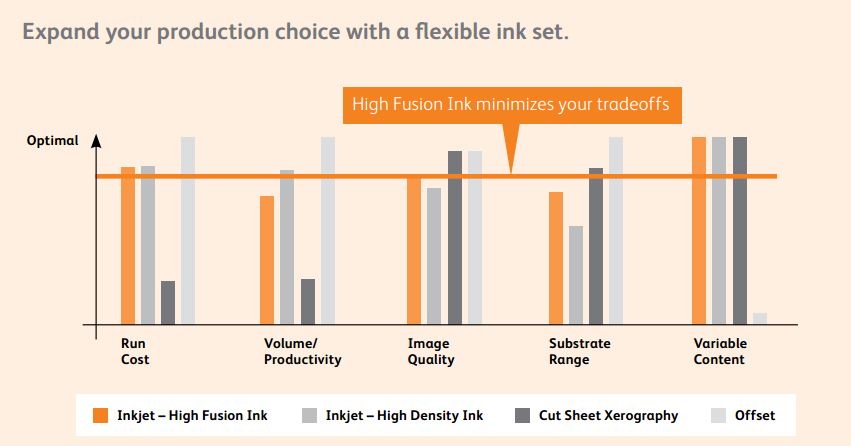

Inkjet printing on offset coated paper presents fundamentally different challenges than printing on uncoated stock. Foremost among them: uncoated stocks easily absorb ink, whereas coated stocks do not. Inks designed for uncoated stock, like Xerox HD (High Density) inks, are formulated for low absorption, to sit on top of the page and provide denser coloration. In contrast, coated papers are less porous and require inks with greater adhesion, as reflected in the name, “High Fusion” Ink.

Drying is also a bigger issue for coated stock because the ink sits higher on the surface of the paper. To that end, the Trivor press is equipped with more efficient and powerful dryers, which along with ink formulation and controlling the amount of ink laid on the page ensures proper curing for image durability.

Tapping into New Book Printing Opportunities

We’re making these investments because the opportunity for inkjet printing on offset coated substrates is significant. As run lengths continue to compress and greater emphasis is placed on all the benefits of digital printing (quick turnarounds, lower volumes, personalization, etc.), more jobs that historically had been placed on offset will fall into digital print’s, and especially inkjet’s, reach. The reason? Inkjet provides printers with more flexibility to more efficiently and cost effectively manage their print runs.

In the case of some applications, this transition can only take place if digital technologies can find compatibility with coated stocks.

This is specifically true for two digital print applications destined for double-digit compound annual page-volume growth through 2018: Books and Manuals (11 percent CAGR) and Catalogs (10 percent)1.

Much of this anticipated growth will be fueled by inkjet. Its print-on-demand capabilities already gives publishers the flexibility to print only the volumes needed, helping to eliminate the costs associated with warehousing and excess inventory – a critical advantage in an era where consumer preferences for e-books versus print can be difficult to predict.

But with High Fusion Inks, operations can be further streamlined by potentially standardizing production across both offset and inkjet onto a single stock. This could translate into big cost savings for both the printers and publishers alike by allowing minimal paper SKUs to be kept in house and potentially freeing them to buy off only one paper contract.

In addition, most color books are printed offshore today, limiting flexibility on volumes and turn times, often resulting in overages or shortfalls. Inkjet will enable much of that work to be sourced domestically, enabling greater flexibility in print order volumes and turn times.

Personalization Drive More Opportunities with Inkjet and High Fusion Inks

Books aren’t the only application that can benefit from the marriage of production inkjet and offset coated stocks.

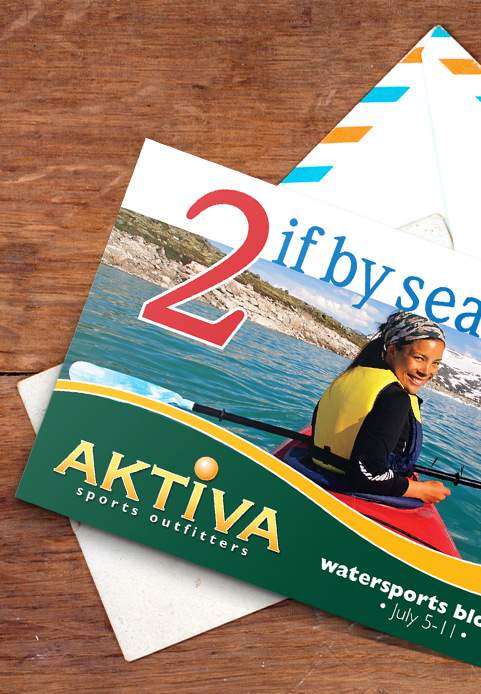

Huge opportunities exist with catalogs and direct mail, both of which have traditionally been printed as static pieces with very little personalization and analytics applied.

With inkjet, printers can satisfy large volumes cost-effectively and in a single-pass, while incorporating variable data that drives relevancy through messaging and offers. This approach has proven to result in significantly more valuable communications with drastically higher response rates and ROI.

In the catalogs space, hybrid approaches can be implemented that combine high-value digitally-printed pages with static offset body pages. With direct mail, the uncoated market has already benefited from what inkjet technologies can deliver, but there remains a very large untapped segment that will soon be able to reap the same benefits.

The coated stock phase of the inkjet revolution is about to begin. Is your business ready to benefit?

1 Source: Smithers Pira [2015] and Xerox Analysis