Thirty years ago, there was only one way to manufacture books – that was by using offset printing technology. More specifically, web offset presses were used for book blocks and sheet-fed offset presses were used for book covers.

Fast forward to today, and inkjet production printing has been revolutionizing book printing for several years now.

Market research company, InfoTrends, reports that production color digital book printing accounted for 16.7 billion impressions in 2013 and they expect this to grow to 52.3 billion impressions in 2018. Of the 52.3 billion impressions, about 87% of the volume will be produced on production inkjet systems.

The business of the book printing and publishing has  changed dramatically due to new printing technologies as well as market changes. The market change for book printers is the decline in the number of books printed at one time, also known as declining run lengths. The technology changes include both toner based (electrophotographic) and inkjet printing. While traditional offset presses remain an important part of the mix for books requiring long-run lengths, digital and inkjet production printing is becoming more important.

changed dramatically due to new printing technologies as well as market changes. The market change for book printers is the decline in the number of books printed at one time, also known as declining run lengths. The technology changes include both toner based (electrophotographic) and inkjet printing. While traditional offset presses remain an important part of the mix for books requiring long-run lengths, digital and inkjet production printing is becoming more important.

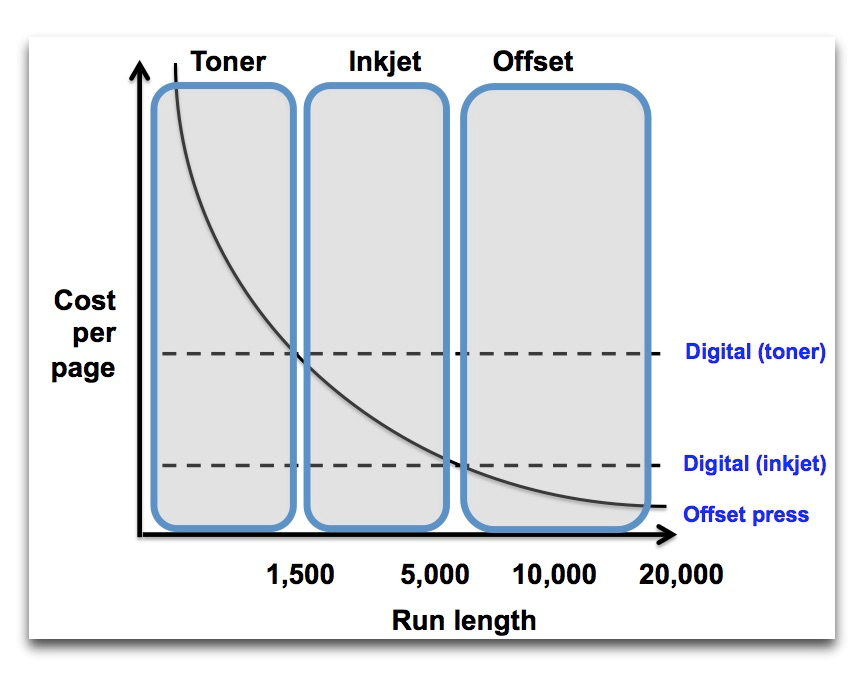

Run lengths are important because while offset printing is much faster once printing is underway, it is more costly during the startup because of plate production, proofing and paper start-up waste. We have devoted a series of articles on the cost of waste (available on the IMG site) and we’re seeing those costs driving a lot of decisions towards digital and inkjet production press purchases. Digital printing using toner or inkjet technologies does not require printing plates, specialized proofing and press make-ready waste.

This can be illustrated by creating a figure known as crossover chart which calculates the cost per page or total cost per book based on run lengths. Cost per page is relatively easy to calculate based strictly on printing costs. However, the total cost per book is more complicated when you have to figure out the costs associated with the manual labor, finishing equipment, machine costs, and the always troublesome time and space costs associated with finishing.

This chart helps to illustrate the cost per page calculation. Where the lines cross are called the ‘crossover points’. It’s important to understand that this is just an example of crossover points. More automation in any printing or finishing technologies will reduce the manufacturing costs and drive any of these lines down.

Calculating the crossover point based on the total cost per book requires a more in-depth analysis that includes the number of pages per book, different bindery technologies, savings associated with electronic coalition, costs of specialty papers (inkjet), inks, and a host of costs associated with the finishing (equipment, labor, utilization, and the lower print utilization rates associated with in-line finishing).

On a recent assignment we recommended a complete refresh of printing equipment for a large book printer. The cross over analysis was critical in helping to define new web and sheet-fed presses. The new offset presses were replacements, while the most significant opportunity was in continuous feed inkjet presses. We predict shifting the shorter run books from offset to inkjet will result in about a 50% reduction in waste.

—

Howie Fenton is the Vice President of Consulting Services for IMG. For 25 years, he has focused on benchmarking operational and financial performance for enterprise and commercial printers. For more info, e-mail hfenton@imgresults.com.

4 Comments

Comments are closed.

The logic is like this ” the longer you do the higher the cost”

so whether you carry on the cost for ink-jet or go with the cheaper one but it takes a lot of your time.

Nice information in a short article. Thanks for sharing this beautiful information.

Inkjet is the future and with the speed that technology is changing and with all the burden costs involved with offset print that increasing, eventually InkJet will be at lower total cost of ownership. I see it everyday, When my team works with a client on Inkjet solution to move from offset, We haven’t ran into many situations where Inkjet TCO was more than Offset.

Brian Ruiz

Xerox Corporation

Program Manager

Production Printing, Software, Technology Expert

Brian.Ruiz@xerox.com

(714) 310-8684

Connect With Me:

http://www.LinkedIn.com/in/BrianRuiz

http://www.TheBrianRuiz.com

Currently we are using the services of Earth First Printing company and the site is Print.org.nz.

Could someone let us know same kind of other companies as well. We would like to compare them all.