For print providers seeking viable production solutions to address large volumes of personalized print, both practically and economically, the cupboard has historically been bare.

Offset presses have struggled to provide the much-needed agility to accommodate today’s personal communications. Toner solutions, despite delivering the advantages of personalization, have economics best optimized to lower volume bands. Meanwhile, the volumes required to justify an investment in 20” roll-fed inkjet color devices have put these solutions out of reach for many.

Up until recently, the space between the highest volume xerographic presses and the lowest volume inkjet presses has been an unfilled vacuum.

But that is all changing.

As of just recently, a new wave of entry production inkjet presses (where acquisition can be justified by volumes generally between 500,000 to five-million) have reached the market. They deliver an optimal combination of cost, speed and productivity for high-volume variable jobs.

Leading the charge is Xerox, who has introduced not one, not two…but three entry production inkjet platforms. With multiple points of entry, providers are permitted to choose the inkjet solution that best fits their workflow, floor space, application mix, price point and growth strategy – among other considerations.

The Coexistence of Inkjet, Xerography and Offset

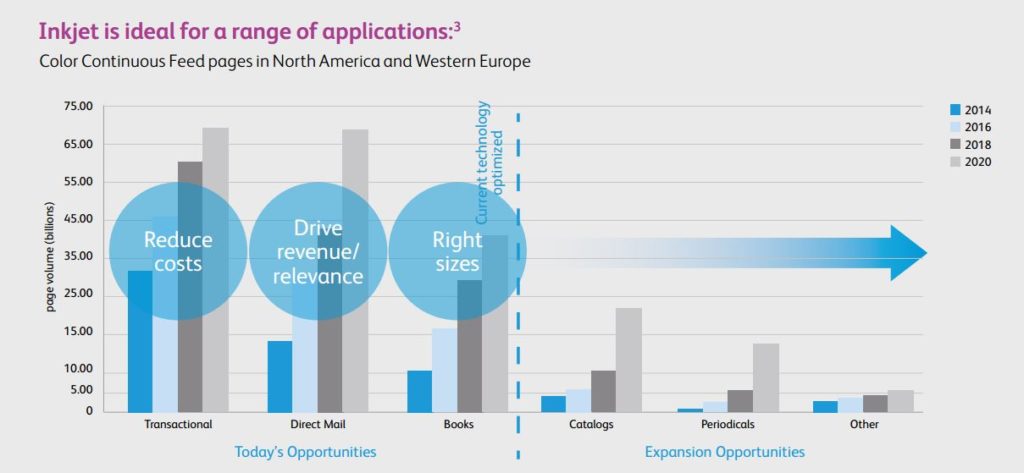

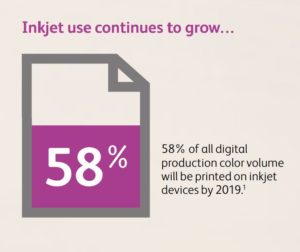

By reaching lower volume bands, inkjet – for the very first time – has become attainable to print providers of many sizes.

By reaching lower volume bands, inkjet – for the very first time – has become attainable to print providers of many sizes.

But does this signal the eventual demise of offset and xerographic technologies?

Actually, quite the opposite.

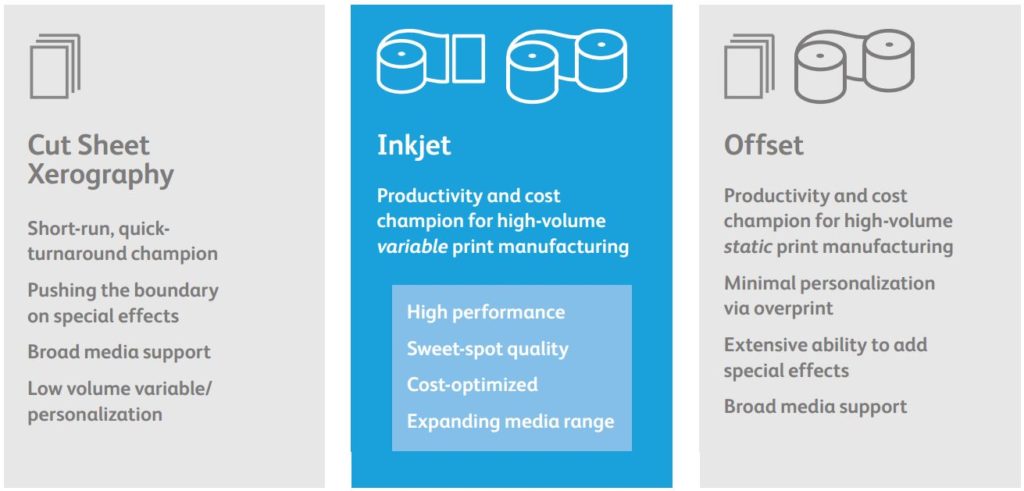

Now more accessible than ever, inkjet is becoming a complimentary technology, filling gaps and helping bridge the worlds of xerography and offset.

The result is unlocked sweet spots between speed, economics, productivity and quality.

We call that ‘right sizing’ your operation: putting the right print technology in the right environment for the right application. And it’s enabled by choice.

By developing multiple entry-level platforms, Xerox is empowering your business with the broadest set of choices – helping you find the right bridge into the world of inkjet.

Examining the Savings and Growth Opportunities Afforded by Entry Production Inkjet

In weighing an investment in entry production inkjet, a natural place to start is the ROI. Will you reap what you sow?

To answer, you’ll need to look at both sides of the ledger: the cost savings it will provide and the growth opportunities it will enable.

On the savings side, providers with an older fleet can consolidate volume, helping eliminate inefficient, old equipment while introducing more productivity-boosting technologies.

Speaking of consolidation, labor can be reduced as well. Press operators that are familiar running xerographic sheet-fed devices can pivot in place and confidently run an entry inkjet press.

Some may also add redundancy, which enables print providers to remain productive even when one press is down for maintenance. High-end inkjet presses with multi-million dollar price tags put redundancy out of reach for most providers, but entry-level presses make redundancy attainable.

Over-manufacturing print is also eliminated by reducing turnaround time and waste. Consider that the traditional way of doing things called for thousands of preprinted offset shells to be printed and stored until a small amount of personalized information was added digitally. Jobs required multiple passes and multiple people. And to make sure enough of the offset shells were on hand to compete a job, a percentage was often unneeded and thrown away.

On the opportunity side of the equation, the economics of inkjet enable providers to migrate more of their work to higher value digital and color printing. This allows providers to develop new high-value applications, for example, using variable information and on-demand turnaround to deliver the right message to the right person at the right time.

Providers can also offer new levels of service, such as Web-based repositories from which customers can order their marketing assets for on-demand printing and delivery.

Another opportunity afforded by entry production inkjet is the newfound ability to handle jobs that previously were turned away or outsourced. Bringing work back in-house while drastically speeding turn times can provide a big boost to bottom-line. And because of its smaller footprints and lower price points, adding additional capacity can help you better meet customer needs.

Choice Matters

Xerox is the first company—and still the only one—to provide a full range of entry production inkjet choices, in some of the industry’s smallest footprints, to meet the requirements of many small and mid-sized businesses.

- Cut-sheet inkjet devices will appeal to cut-sheet xerographic print providers. Xerox addresses this need with the Xerox Brenva HD Production Inkjet Press, which is built on the same frame as the Xerox iGen series, the company’s flagship xerographic press, and shares many operational functions as well.

- Those who want the productivity of a continuous feed inkjet press along with the operational simplicity of cut-sheet digital will be interested in the Xerox Rialto 900 Inkjet Press, our narrow-web continuous-to-cut-sheet solution. All the componentry needed to turn continuous feed white paper into a printed, cut sheets is under the skins, activated by a large smartphone-like interface for simple operations.

- For traditional web offset print providers who are moving into this market space, a continuous feed inkjet press eases the transition by offering a more familiar workflow and opportunities to leverage existing paper handling equipment. For them, Xerox offers the Xerox Trivor 2400 Continuous Feed Inkjet Press.

These entry points make good sense as they represent each of the three basic inkjet configurations: cut-sheet, roll-to-cut sheet and continuous feed.

In mapping these paths forward, Xerox is leading the effort to democratize inkjet printing, bringing the segment’s opportunities to life for a wide range of small and mid-sized print providers. This is a stark difference from competitive offerings, which typically only offer choices between a single entry-level model and big iron with high price tags and intimidatingly high volume requirements.

Now, Any Operation Can Deliver New Value

Not all print providers come from the same background and they certainly do not all have the same goals in mind. That’s precisely why having this choice flexibility is critical. One size does not fit all.

Together with the industry’s broadest and most complete set of toner cut-sheet devices, as well as an award-winning suite of workflow solutions, finding the right migration path to an entry production inkjet platform right for you has never been easier.

With multiple entry points, emerging synergies between other printing technologies and a clearly defined path forward, this technology is unlocking the new value of print – helping providers and customers alike reap its many benefits.

This is a great way to look at where inkjet fits into the greater Graphic Communications mix. What’s more, it offers the opportunity to change what is delivered to the marketplace, for acquirers and specifiers. We are seeing the transition of how books are created and exist both in hard and soft formats, how transactional documents are delivering stronger marketing messages and how direct marketing vibrates from multi channel media through to print based on consumers preferences rather than the industries.

Great read by Bill Michael, great lead by Xerox.

Great Overview on inkjet.

If you interest in a webinar about inkjet i have one that great…

Sincerely,

Brian Ruiz

Xerox Corporation

InkJet Specialist

Western Region

Software, Technology, and Business Development Consulting

Brian.Ruiz@xerox.com

(714) 310-8684

Connect With me:

http://www.LinkedIn.com/in/BrianRuiz

Twitter: @TheBrianRuiz