“I think this product could become the de facto standard for photo books because of its quality.”

That was the assessment of Frank Romano, professor emeritus, Rochester Institute of Technology, five years ago in reference to Xerox’s launch of the Color 800 and 1000 Presses, which brought the unique capability of in-line clear dry ink coating to the toner-based world. An optional fifth toner station gave print providers the ability to add spot, flood or multiple layers of coating to printed output in the form of creative and textural effects as well as variable information.

In a competitive marketplace, the ability to add clear toner represented a way for print providers to easily stand apart and differentiate. It increased the value, and margin, of a sheet by helping providers to sell it for more. Fast-forward to present day, and print providers in search of even more competitive advantages may have struck gold, literally.

The recent launch of the Xerox Color 800i/1000i Presses expands the Specialty Dry Ink portfolio beyond clear, enabling providers with the ability to enhance print with true Pantone® metallic gold or silver inks.

Let’s take a look.

New Improvements. New Name.

The enhanced Xerox Color 800i and 1000i Presses bring many new improvements to a class-leading technology that has established a reputation for helping print providers flourish over the years. So what does that “i” in the new name actually stand for?

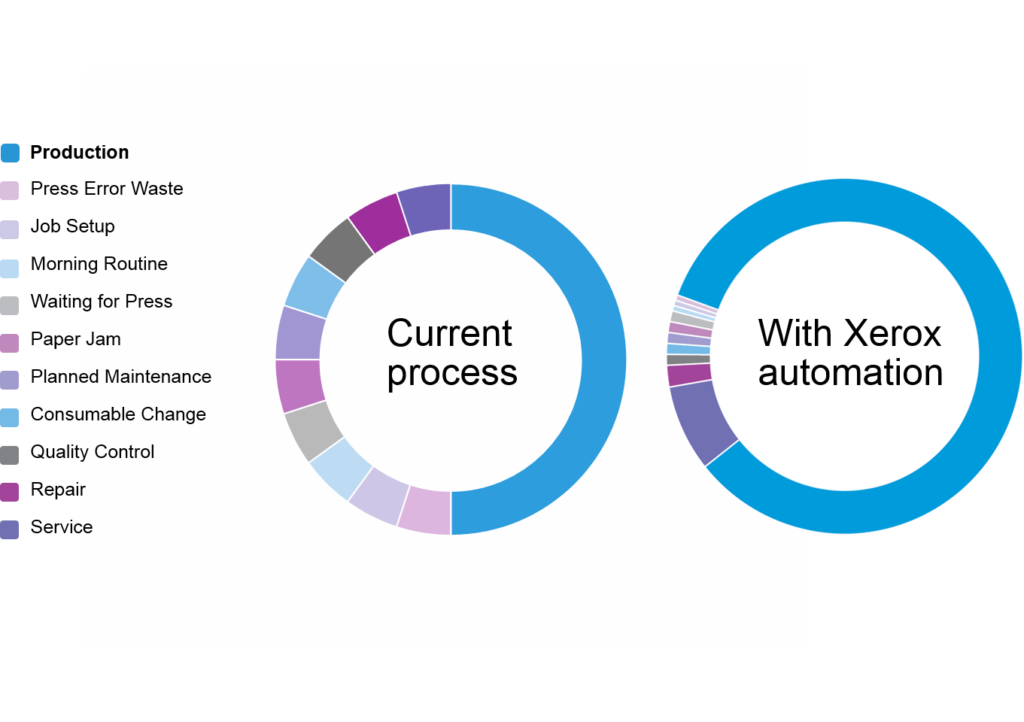

That’s simple. It represents increased press availability, as in more time spent producing profitable jobs and less time expended on tedious setup tasks (robust automation features, such as Full Width Array and Auto Sheet Clearing come standard, for example).

It means you’ll have more creative freedom when it comes to inventive high-value applications (through the addition of true metallic gold and silver inks, both of which carry Pantone designations – 871C for gold and 877C for silver).

And it signifies innovative workflow offerings, such as IntegratedPlus automated color management and IntegratedPlus finishing options, delivering incredible automation.

But most importantly, all these incredible productivity features translate to increased revenue for you and your operation.

Automation Comes Standard

Your customers expect high quality print, that’s a given. And for the most part, any digital press on the market these days can deliver that. But not every press can ensure that the first print and the thousandth print look identical, or that customers coming back to you weeks, or even months, after an initial print run will see consistency in what you deliver.

As a result, you may find your press operators spending a lot of time performing ongoing color management tasks, discarding output and rerunning jobs.

Fortunately, the Xerox Color 800i and 1000i Presses come with automated color management systems built right in. This includes a Full Width Array featuring the Automated Color Quality Suite (ACQS), an exclusive technology consisting of inline sensors that span the entire width of the paper path and scan post-fused images on media at rated speeds.

What does this do? It automates time-consuming setup tasks, such as baselining the press for density uniformity and Tonal Reproduction Curve (TRC) calibration, as well as image-to-media alignment. Procedures that previously were reserved for service technicians are now done by the operator at the push of a button, allowing them to focus on producing profitable customer work.

Gold and Silver Metallic Inks

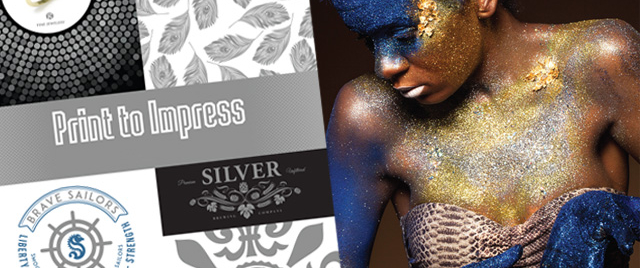

Standing apart and enhancing the creativity and impact of your print is easier, and more effective, than ever before! The Xerox Color 800i and 1000i Presses feature an optional fifth print station that allows you to apply one of three available specialty dry inks, which includes Clear (perfect for spot or flood effects), Metallic Gold or Metallic Silver.

These unique metallic inks are more than digital simulations. They are real metallic inks, complete with metallic flecks embedded in the toner and boast some of the highest flop indexes in the industry. This measures the change in reflectance seen when holding the sheets in various angles with light.

Expand your portfolio of offerings by creating stunning metallic and foil stamp-like effects, without the associated costs of traditional processes (make-ready time investment, custom dies, materials, and waste). Jobs that previously were outsourced for offset gold and silver printing and foil stamping – such as logos, invitations, certificates, report covers, posters, and business cards – can now be migrated to digital and produced inline and at rated speeds, resulting in quicker turnaround times and cost efficiencies.

This is perfect for highlighting logos and images in direct marketing campaigns and drawing attention to static or variable text…dramatically enhancing the look and value of your print!

[youtube]https://www.youtube.com/watch?v=SC5Lx29BuMA[/youtube]

Xerox Color 800i/1000i Press Customer Reviews:

Serbin Print Marketing and Publishing, based in Sarasota, Florida, describes their experiences using the Xerox Color 1000i Press and the impact the gold and silver metallic inks have had on their business:

[youtube]http://www.youtube.com/watch?v=SgCyT_VCT-M[/youtube]

Harvard Pinnacle Group, based in Waltham, Massachussets, shares their impressions after investing in the Color 1000i Press with gold and silver metallic inks:

[youtube]http://www.youtube.com/watch?v=C0hTP6gA_oU[/youtube]

Have Questions? We Have Answers!

- I currently have a Color 800/1000 today. Can I upgrade to the Color 800i/1000i?

Yes, upgrades for existing Color Presses will be available in May 2015. Contact your Xerox sales rep for details. - Are Metallic Inks available for other Xerox Digital Production Presses?

No, the Specialty Dry Ink suite (Clear, Gold and Silver) are exclusive to the Xerox Color 800i/1000i Presses. - Are the Gold and Silver Inks truly metallic?

Yes! They are true metallic Pantones, 871C (Gold) and 877C (Silver). - Can I run Gold, Silver and Clear at the same time?

No, unfortunately not. In addition to the four print stations (C, M, Y and K), the Color 800i/1000i Presses utilize a fifth station which allows for the inclusion of one specialty dry ink at a time: either Clear, Gold or Silver. - Can I swap between Specialty Dry Inks on my own?

Yes, users can swap between Gold, Silver or Clear Specialty Dry Inks without needing to place a service call. The process simply involves pulling out one developer housing and replacing it with the other. There is no clean-up, vacuuming or toner loss and the process takes less than 30 minutes. Watch our brief demonstration. - Can I add texture to my print?

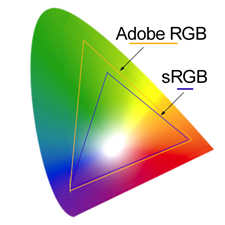

Yes, Xerox Multi-Pass allows users to add up to seven layers of Clear Dry Ink to an application. This is done at the print server and without the need to manipulate the job source files. With Metallic Gold and Silver, it is not recommended to use more than two passes. For tips on how to design for multi-pass printing, please watch this video. - When designing in Adobe Photoshop, Illustrator or InDesign, how do I set-up the Gold and Silver inks?

Please refer to our tutorial videos on how to set-up the gold and silver metallic inks in Photoshop, Illustrator and InDesign. - How do I set-up Metallic Dry Inks on my Print Server?

Setting up Metallic Dry Inks on your print server is very easy, but the process varies depending on your DFE. Please view out video demonstrations for either an EFI or FreeFlow Print Server. - Where can I purchase Gold and Silver Inks?

Specialty Dry Inks (Gold, Silver and Clear) can be purchased here.

What are your thoughts on metallic inks? Interested in learning more? You can read about other opportunities with inks in this popular post: Expanding Palette of Metallic Inks Offers Bright Opportunity

Comments are closed.