For today’s converters, “agility” is more than a buzzword; it’s a vital part of any long-term business strategy.

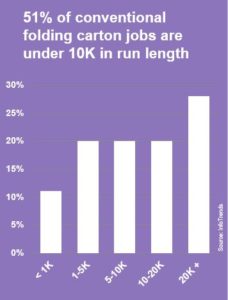

Brand owners are more focused than ever on market versioning, targeting, product variation, personalization and customization. Shorter runs is what the future is trending towards. In fact, more than 50 percent of conventional folding carton jobs are already under 10,000 in terms of run length.

This means changes could be looming on the horizon for many wide format carton applications, such as cosmetics, food and pharmaceuticals, all of which have traditionally been produced on analog technologies. As these new demands become more commonplace, emerging revenue opportunities will continue to knock on the door of converters with digital technologies in place and the expertise to engage.

For this audience, digital represents the one ticket to increased agility. No longer a novelty, it is finally ready to shed its image as being purely a specialty technology and become a full-on packaging player. In fact, analysts project digitally-printed folding cartons to grow by 40 percent annually.

A First-of-its-Kind Press

Back in 2010, we introduced the Xerox® Automated Packaging Solution for the Xerox® iGen® Press. Designed to be an entry-level offering for converters and printers, this was the first integrated, inline digital solution for packaging.

Now, we are happy to introduce another first that we believe will change the future of digital folding cartons.

As the leader in digital printing, we have partnered with the leader in offset package production, KBA, to bring a completely new B1 sheet-fed technology to market: The KBA VariJET 106 Powered by Xerox.

With installations to start in 2017, this technology integrates Xerox® Impika® inkjet technology into the KBA Rapida 106 press platform. The result? Industrial production printers get the strengths of digital inkjet printing such as versioning and customization, plus the benefits of classic offset printing and inline finishing.

Capable of knocking out 4,500 7/0 B1 sheets per hour, one of the major hallmarks of this hybrid machine will be its versatility. On the pre-treatment side, users have the option of adding enhancements, including offset printing and cold foil. When it comes to post-treatment, the options are equally as expansive with the possibility of offset printing, cold foil, rotary diecutting, creasing and perforating inline.

“The key distinction from other digital press offerings targeting this space will be the modularity design options available based on specific customer needs,” offered Mark Michelson, editor of Printing Impressions, after speaking with leadership from both KBA and Xerox. “The VariJET 106 can be configured as a seven-color, inkjet-only press incorporating Xerox Impika inkjet modules, or as a hybrid press incorporating both inkjet and traditional offset printing units.”

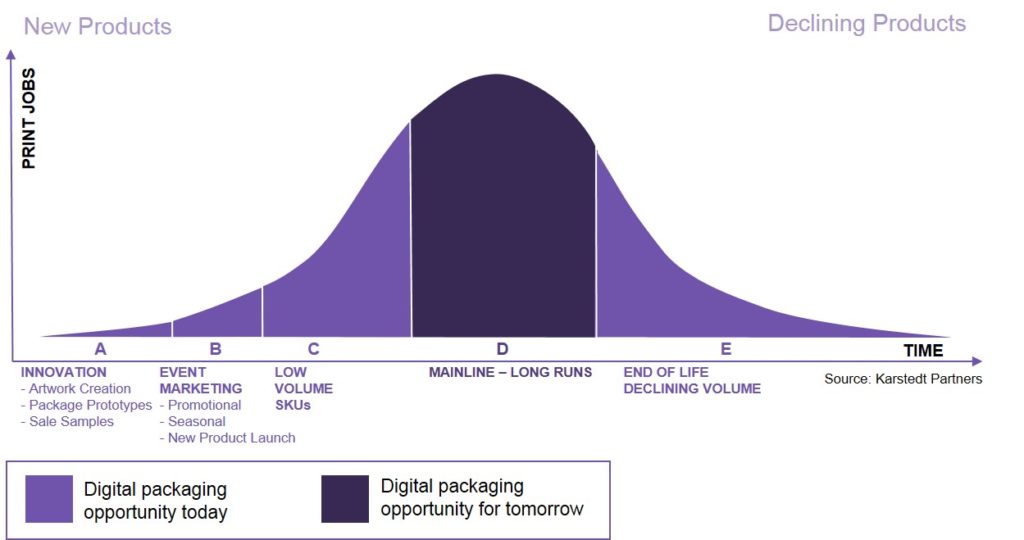

What was once primarily used for things like prototypes, sales samples and seasonal marketing, now represents a good chunk of the future of the market. With this press, providers will be able to handle everything from low volume SKUs and long runs to mainline and end-of-line declining volume jobs. That, of course, is in addition to enjoying the classic benefits of digital, such as just-in-time delivery and reduced warehousing.

Want to Learn More?

To discover more about this machine before it hits market in 2017, check out the full press release. Want to hear what the industry is saying? Check out these insights from Mark Michelson, Editorial Director of Printing Impressions, and consultant David Zwang.