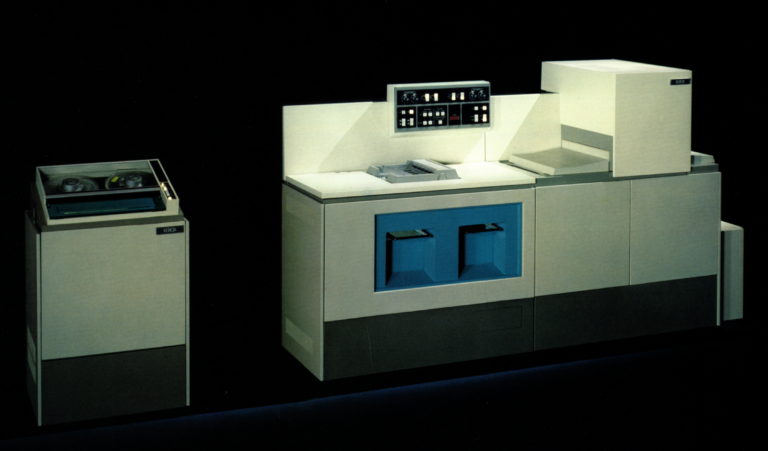

Gary Starkweather invented the laser printer in 1969 while working in a Xerox research lab, and he played a key role

in developing the company’s first laser printing product, the Xerox 9700, which was announced 40 years ago this month. His invention spawned the digital printing industry, which today generates more than $120 billion in global annual revenues, according to Smithers Pira. It earned him a spot in the National Inventors Hall of Fame—he was inducted in 2012—and it is a major reason why Xerox was the only printer and press manufacturer in the launch of the Smithsonian National Postal Museum’s virtual exhibit, “America’s Mailing Industry.”

Indeed, Starkweather’s invention has been at the heart of very successful Xerox businesses serving production facilities and offices for 40 years and is expected to remain a foundational technology for years to come.

We recently took the opportunity on this 40th anniversary of the 9700 to catch up with Xerox and industry giant Gary Starkweather from his home in Lake Mary, Fla. Here are some edited excerpts.

Did you ever imagine your invention would have the impact it has had?

We envisioned quite a bit. Since the laser printer printed with points (rather than with fully formed characters), we could print anything, and thus the 9700 could print any kind of document. But (former Xerox Chief Executive Officer) Dave Kearns put it to me very well when he said, “We have a seven-year plan and we plan the future with great precision, but we have no idea what we are doing on Tuesday

How did you first decide to try to print with lasers?

My first job at Xerox was working on LDX, short for Long Distance Xerography (an early fax machine). The LDX used a cathode ray tube to generate its scanlines for scanning and printing. At the time, they gave me the problem of making the system’s scanline brighter as a way to increase scanning and printing speed. The problem was that the cathode ray tube couldn’t be made any brighter without seriously affecting the lifetime and practicality of the system.

So I looked at the universe of available light sources to find a very bright, well-defined light source. The laser had been invented six years earlier, in 1961, but was still fairly new technology. I found that its potential as a cathode ray tube replacement was very high. As I got deeper into this issue, I asked myself, why not send bits in character or other form to the receiving end of the machine to print instead of scanning a printed document and sending the scanned image over the wire to the receiving machine? My proposed solution was experimental, so I made a prototype in 1968 and1969 as a crude machine that could scan and print in the lab. I found the laser solved all the key problems with the cathode ray tube, and there were no showstoppers to developing the solution. So I filed some patents on the system. I didn’t get to develop the laser printer at that time because some in management felt it was an impractical machine. As a result, I transferred from the Webster (N.Y.) research center to the (then) newly opened Palo Alto Research Center (PARC), where laser printing fit in better with the mission and goals of the PARC future vision.

What were some of the key discoveries that led to your invention?

There were two main breakthroughs. One was that the little spinning mirror (which the laser beam bounces off of to “write” the page). This spinning mirror had about 20 to 30 facets (small, polished plane surfaces) and had to be extremely precise. The laser beam’s pointing accuracy from the facets couldn’t be off by more than the diameter of a dime at the distance of a mile. This is a very precise requirement in principle. Spinning mirrors could be made to this accuracy but would have cost $20,000, and that was far too much for a mass-produced product.

Since I was an optics graduate from the University of Rochester, I was schooled in the issues and sketched out possible solutions to this problem on a piece of paper. One day, I looked at my diagram and I said to myself, “Oh my goodness, that’s a cylinder lens. It can’t be the answer, it’s way too simple.” But I ordered a cylinder lens, got it in three days and tried it out. It worked. This was as close to a “Eureka moment” as I’ve ever had. The cost of this critical component went from $20,000 to $10. Today such mirrors are made for personal laser printers for about $3—mirror, motor and all.

The other breakthrough was that the best available lasers to use produced red light. The photoreceptors in Xerox machines were not sensitive to red light, which meant that I couldn’t use red-light lasers without a special photoreceptor. Then one day I got a call from a fellow in manufacturing. They were putting together a production prototype copier that would have five copy reduction sizes. However, the unit was flawed in its optical design. The only practical solution for a fix was to put a red-light sensitive drum in the machine. This problem and the red-sensitive drum solution is what enabled me to use a red laser in my prototype. What a fortunate situation for me as well as Xerox.

With those two breakthroughs, my two biggest problems just went away. It goes to show—sometimes it’s better to be lucky than to be smart. As Albert Einstein said, “Imagination is more important than knowledge.

What markets were you targeting, and how did your approach differ from your competition at the time, the IBM 3800?

We were going after the document market. In contrast, the IBM 3800 was really designed as replacement for a line printer. (Editor’s note: line printing was the leading technology for printing from mainframe computers at the time, making marks on paper by striking an ink-filled ribbon, like a typewriter.) The quality was considerably lower (initially 144 dots per inch versus 300 on the 9700), which was adequate for a line printer, but not for a document printer. And it used fanfold paper, which requires post-processing.

We could have cared less about line printing—that was an hor d’oeuvre. We wanted the speed, quality and reliability to replace document production, to print logos and reports and documents that look very much like an office document. We built the 9700 to have high print quality and reliability and to be productive for the user, to feed single sheets and to have a complete document stack came out of the machine. IBM never made a dent in our sales.

Many inventions are made by teams. Was that true of laser printing?

Not really. I had a great technical assistant, Bob Kowalski, who wired things up for me. And of course I built upon technologies that other people had developed, like the copier. But we were a team of two, working on my invention. There were no task forces or anything.

What was your role in seeing your invention productized?

Xerox started a printer engineering operation in Dallas, and I worked with them for two years to help develop the 9700. Previously, I had built a prototype at PARC and its basic optical system was used in the 9700. The PARC prototype printer, called “EARS,” became so useful that everyone printed their output on it. We ran it for several years, and it worked virtually 100 percent of the time. This indicated to us that no significant engineering issues needed to be addressed for the 9700, although the 9700 team worked hard on some new laser technology for the product. One key improvement in the 9700 was that the print speed of the machine was increased to two pages per second (our PARC prototype was one page per second). We did it by down-rating the 500 spots-per-inch page resolution to 300, so the demands on the system electronics were similar.

The 9700 became a wild hit. Early estimates projected that only 600 units would be sold. Actual selling volume was over 10,000 machines.

Another critical consideration after the 9700 launch was the concept of a personal or small-volume printer. We thought, “Why don’t we do a small machine?” So we built a printer on the Xerox model 3100 copier and we showed it could be done. However, the marketing and product planning people couldn’t see where the money was to be made with such a device. It wasn’t until 1980 that Xerox saw the money could be made in paper and toner, but by then we were already behind the eight ball. Small laser printers were already entering the market from other vendors.

What other research initiatives did you pursue in your career?

I left Xerox in 1987 to join Apple, where I worked on their laser printing, color management and display technologies. And I later joined Microsoft, where I continued my work on display technologies. A real question was raised at the time about the future of paper and how the printer would survive into the future with people using novel displays etc. Some 40 years later, laser printers are still going strong.

How do you spend your time today?

I’m retired. I’m a model railroader, and I have a garage with a train layout in it. There’s a group of men I meet with from time to time. I’m an officer in my church. I read a lot and try to keep up with the major directions of the tech industry. I also give local talks to engineering students, trying to advise them of how to sell an idea and move it through the corporate structure. I still consult occasionally and enjoy that a lot. And I’m at an age where I have to leave room for doctor’s appointments. It keeps me busy.

What do you see as the greatest technology innovations and challenges on the horizon?

Communications is a big thing today, getting information anytime, anywhere, but we want it to be delivered safely. We started working on these technologies with the purpose of sharing information, not to keep people from obtaining it. How we put security back into the system without destroying the nature of the system’s advantages is a big challenge. Eventually, it’s all ones and zeros, so theoretically, anyone can hack through it and put the bad guys briefly ahead.

What do think about print’s value today?

There a lot of studies comparing reading on the iPad and reading on a book, and some make one or the other superior. In one book, entitled, Word Onscreen: The Fate of Reading in a Digital World, I recall the case of a professor giving her students homework as URLs, and 85 percent of the students printed the pages. Why? Because it’s easier to read and annotate on paper, at least today.

If you talk about an ideal display, you look for something that doesn’t need to have its batteries recharged very often, is portable, easily folded, light in weight, and not subject to serious cost issues if lost. When you’re done with such an analysis for such a display, I think you just described a piece of paper. Maybe we shouldn’t kick paper to the side of the street so fast. After all, it has been around for a long time! Good technology is not about doing it differently but about doing it better and more economically.