At the first Inkjet Summit in 2013, I moderated the book production track and asked companies their cross over points for different printing technologies. I got very different answers. I did not understand the differences at the time. Recently however, I worked with a large book printer and learned that this is a much more complex question than I ever imagined.

Book printing in the last thirty years has changed dramatically due to technology and market changes.

The market change is the decline in the number books printed at one time – referred to as declining run lengths.

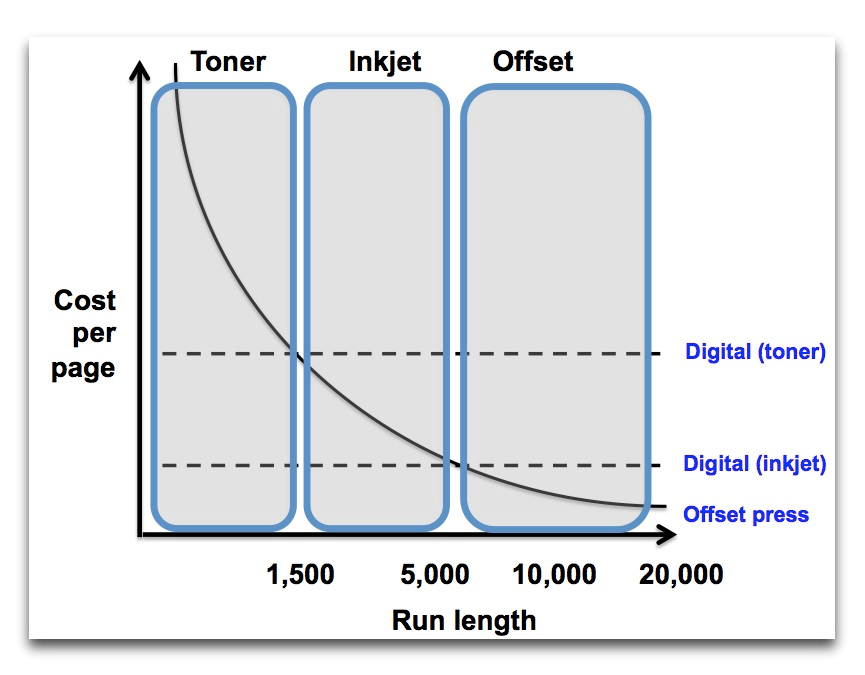

The technology changes are faster toner and inkjet based digital presses. While traditional offset presses remain an important part of the mix, the percentage of books printed with offset technology is declining, while the portion printed with toner and inkjet is growing. Both toner and inkjet have proven more efficient for shorter run lengths. Run lengths are important because, while offset printing is much faster once upon running printing, it is more costly during the startup process.

Many book printers offer all three printing technologies and use the most appropriate technology based on the demand. Long runs are done with offset presses, moderate runs with inkjet, and short runs with toner. The points at which one technology becomes more efficient than another is called the cross-over point.

Calculating the crossover point is more complicated than I thought because the total cost of manufacturing is more than simply the printing cost; it is also the finishing and carrying cost. For example, digital print is slower but can finish the books in-line. In contrast, offset presses print faster but require holding the pages until the whole book is printed and then they are finished off-line.

Also important is the page count of the book. Digital and in-line finishing have advantages for books with fewer pages, while offset and off-line have advantages for books with more pages. And lastly is what some call the cost of carrying inventory which can include:

- Money tied up in inventory, such as the cost of capital or the opportunity cost

- Physical space occupied by inventory, including rent, utility costs, and insurance

- Cost of handling the work.

I was surprised recently to learn how much the carrying costs can be for one client who requires large spaces for storing work in process and staff and fork lifts to constantly move paper.

Those complicating factors are why companies have different cross-over points. At the Inkjet Summit, I asked book printers for the same cross over point of digital and offset and heard answers ranging from 500 to 7500 books. The exact points are different due to the unique answers to the questions described above.

—

Howie Fenton is the Vice President of Consulting Services for IMG. For 25 years, he has focused on benchmarking operational and financial performance for enterprise, in-plant and commercial printers. For more info, e-mail hfenton@imgresults.com.

Interesting article, and a topic discussed many, many times over my time in the industry. I have one query though, surely books with a larger pagination would be better printed digitally in smaller quantities as there you aren’t doing multiple plates or sections that all need to be put together afterwards.

With digital, every page can be different every time, so more pages has no impact on digital.

With Litho, the more of each page, the more cost effective it becomes.