Examining the Inkjet Opportunity

There’s no denying the unbelievable opportunities enabled by digital print, including shorter runs, demand for personalization, and rising pressures to speed turnaround times. An estimated 50 trillion pages are produced worldwide today using production print technology, only 2% of which are printed digitally…but it’s growing steadily at a compound rate of over 8%.

To capture these booming opportunities, to date there have really only been two primary classes of devices: Cut-Sheet Toner and Continuous Feed/Inkjet. Unfortunately, these two technologies have failed to serve the entire marketplace.

For print providers with incredibly large volumes to fill, the productivity and cost-per-page achieved by toner solutions may not be what they need to compete. Meanwhile for some, the acquisition costs and complexities of a full continuous feed or inkjet solution may prove to be prohibitive.

This has created an unmet market need, referred to by InfoTrends as the ‘Zone of Disruption’. Satisfying this void would require a solution that sits between the fastest cut-sheet color toner-based devices and that of high-speed color inkjet continuous feed. It would mean a solution that could provide productivity beyond what toner can deliver, and with the image quality needed to produce a range of applications…but in a smaller, more cost effective package.

Introducing a New Breakthrough in Inkjet Innovation

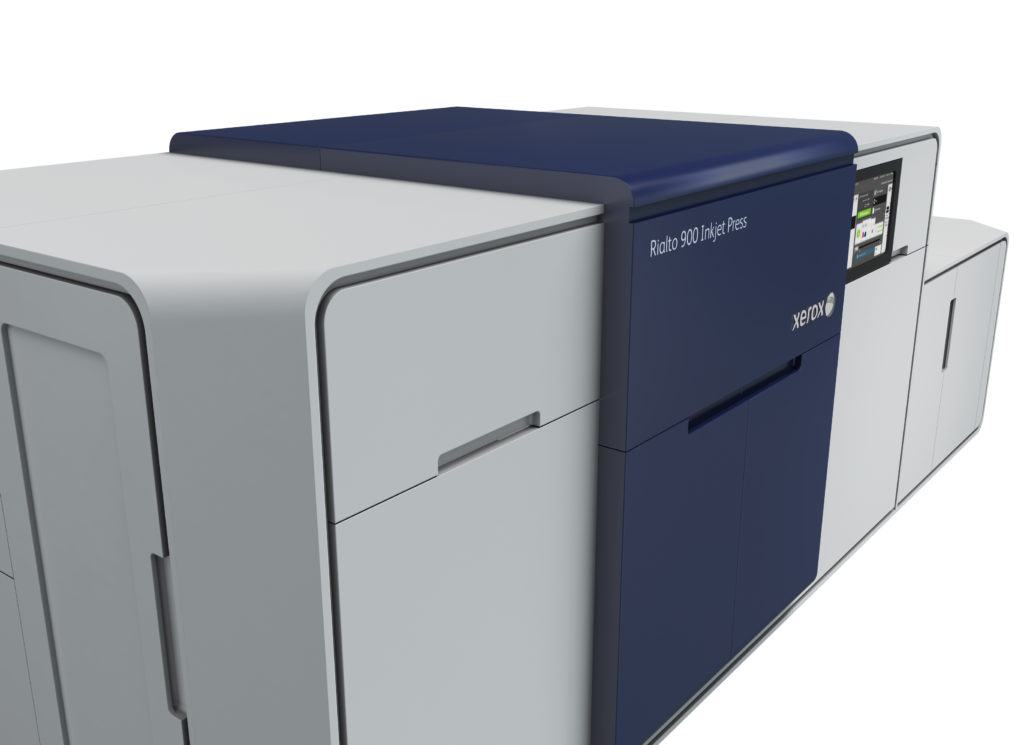

We are thrilled to announce the Xerox® Rialto™ 900 Inkjet Press, the world’s smallest, fully integrated narrow web inkjet solution. And we couldn’t be more excited to reveal it to the world here at Hunkeler Innovationdays.

Similar to the landmark bridge in Venice, Italy, this new narrow-web, roll-to-cut sheet inkjet technology provides a path between the worlds of offset and digital and assists those who are making the journey from cut-sheet to continuous feed.

Now, inkjet technology can be a reality for more print service providers by breaking down barriers such as high print volumes, large footprint and costs. For those who previously saw entrance into inkjet as out of reach, this technology dispels that notion, providing a cost-effective means to deliver everything from mono book pages to high value, high quality direct mail applications.

[youtube]https://www.youtube.com/watch?v=nSnd8rUCgl4&list=PLioPSVdbzdpZHN7MyCsEnX76Y18cS-34X&index=85[/youtube]

It’s time to rethink inkjet and significantly transform your business potential by:

Rethinking Performance

To help lower the entry point into production inkjet technology, the Rialto 900 prints duplex jobs, one-up on the smallest, narrow web (9.84 inches/250 millimeters) on the market. Designed for roll in, cut sheet out performance, it has the smallest footprint of any inkjet press on the market – 11.9 x 5.1 feet (including press tower).

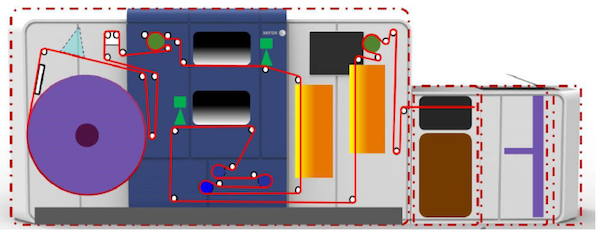

You’ll be able to print at up to 157 feet per minute with single pass duplex, and on a media range of 60 to 160 gsm which includes uncoated, untreated, inkjet treated and inkjet matte coated substrates.

You’ll be able to deliver high-quality prints with 1000 x 1000 dpi visual resolution, complete with smoother gradients, tints and sweeps and sharper details, lines and text for transaction, transpromo and direct mail jobs.

Rethinking Efficiency

This is the world’s first narrow web inkjet press with an all-in-one integrated white paper-in, roll-to-cut sheet design. Nearly everything you need to achieve maximum production inkjet power is wrapped up in one easy-to-use package, simplifying the process of delivering high-value inkjet jobs.

The press’ simple design and straight paper path not only reduces the overall footprint, but also helps remove the inherent complexity of meeting time-critical SLAs.

Rethinking Flexibility

You can now move jobs from offset, cut-sheet digital or higher-end inkjet in a much more efficient manner. For example, if you had previously been outsourcing specific jobs, such as offset shells, to other commercial printers, you can now bring all that work back in-house onto a single press. Additionally, there is now a cost-effective solution to adding peace of mind and redundancy to your operation.

Could adoption of high-speed production inkjet technology make a difference in your business? What opportunities do you see?

Comments are closed.