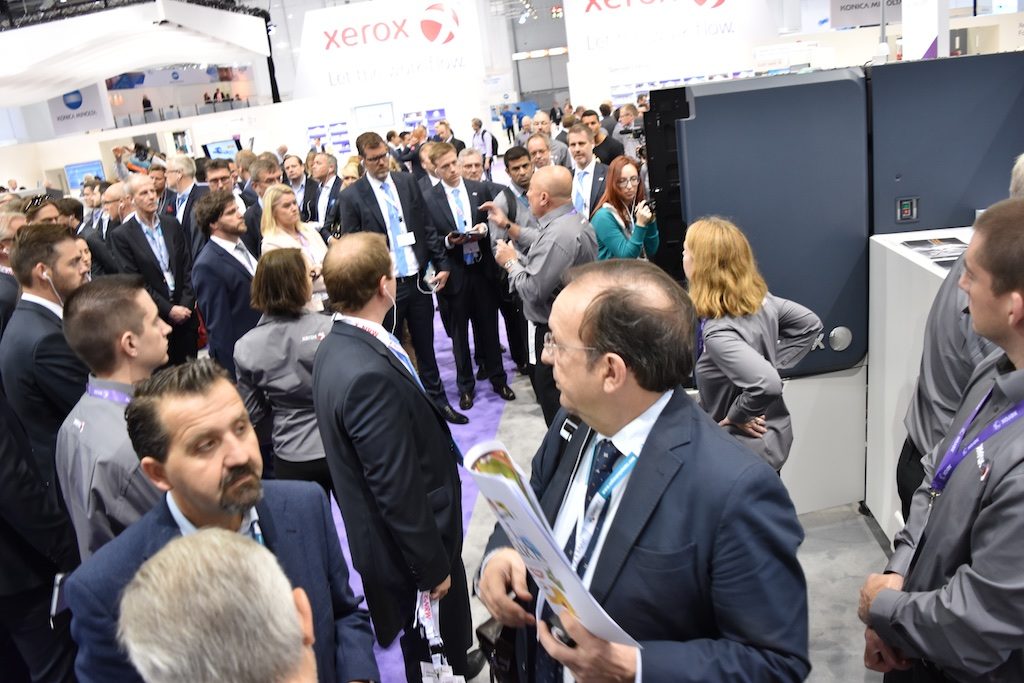

The ‘Olympics’ of the print and graphic communications industry opened its doors this week, welcoming what is expected to be over 300,000 visitors from more than 130 countries. Comprising the Messe is 17 halls for visitors to explore, filled with the latest in workflow software, substrates, post-press machinery and technology from all processes of print.

What exactly is the importance of this quadrennial tradeshow? Perhaps Jeff Jacobson, President of Xerox’s Technology Business, said it best:

“If you think about the evolution of this industry over the last 25 to 30 years, drupa is usually the landmark where the technologies that pave our path forward are unveiled.”

If drupa truly is the North Star, guiding us to where our industry is headed, then what exactly drew the biggest buzz after week one?

This recap will break it all down for you (but first, check out the highlight reel below):

[youtube]https://www.youtube.com/watch?v=_uTMtWeaKDo[/youtube]

Collective gathering of an industry

One day prior to drupa opening its trade fair doors, over 600 of the brightest minds in the print industry gathered at the Xerox Premier Partner Forum for a day of networking, learning, collaboration and fun. This group included members of the Xerox Premier Partner Global Network, consisting of some of the top print providers in the industry, as well as Xerox Graphic Communications resellers.

Sessions included Marco Boer, Vice President of I.T. Strategies – who offered a glimpse into the state of the industry and emerging segments, as well as Carlo Alberto Carnevale Maffe, Professor at Bocconi University – who shared insights on how print providers should be differentiating themselves.

The highlight of the day? A breathtaking display of true collaboration, as guests were given drums and sticks, playing together in rhythmic harmony. Collectively as a group, the room showed that the network, and industry as a whole, has a very strong beat.

Want to experience the event for yourself? Here’s a taste:

[youtube]https://www.youtube.com/watch?v=D2b5_xuRUjI[/youtube]

Industry-wide recognition

Also at the Premier Partner Forum, winners of the Xerox Best-of-the-Best program were awarded. Recipients reigned from 14 countries with the Best-in-Show winner, Printagraph Ltd. of the United Kingdom, developing custom LEGO-style brick kits with personalized packaging.

In addition to our customers, two Xerox technologies received industry recognition:

- The Xerox Rialto 900 Inkjet Press, which received an award from the European Digital Press Association (EDP) best Inkjet Roll-to-A4 cut sheet device.

- The Xerox C60/C70 Printer was honored with a BLI (Buyers Laboratory) PRO Award for Outstanding Color Light Production Device. It was noted for its versatility and quality, registering the densest black measured on a digital press in its class.

Technology

Inkjet

Headed into drupa, much of the buzz was surrounded production inkjet…and it did not disappoint.

Shown for the first time publicly was the Xerox Brenva HD Production Inkjet Press, a cut-sheet inkjet technology that many industry analysts have pegged as a ‘true market disruptor’. The reason? It is uniquely positioned to sit between high-end cut-sheet and low-end inkjet, delivering the economics and productivity benefits of inkjet to print providers for whom this technology was previously out of reach.

Also making its world-wide debut was the Xerox Trivor 2400 Inkjet Press, a next-generation inkjet platform that provides incredible scalability, flexibility and enhanced productivity. With color print speeds of 551 feet/168 meters per minute, this system offers a 30 percent productivity bump over the entry-level Impika Compact model it replaces.

Gazing into the future of packaging printing

Direct to Object

How would you like to personalize any object, from bottle caps to basketballs?

How would you like to personalize any object, from bottle caps to basketballs?

That is now possible and on display at drupa with the Xerox Direct to Object Inkjet Printer. Show attendees can have their name printed directly onto an aluminum water container, or their face printed onto an earbud case.

This technology allows you to print on three-dimensional objects and a variety of substrates with ease.

Most exciting is the fact that less than 1% of printing for direct-to-object is done digitally today, but that is expected to grow at a 44% CAGR from 2015 to 2019 (Smithers Pira, 2016).

Marking and Coding

For late-stage customized printing, current technologies just don’t satisfy today’s demands.

Consider packaging applications such as food and beverage, corrugated packing boxes, and retail products. Typically, a second production pass is required to produce OCR, QR, and 2D Matrix codes; variable product information; date and lot codes; bar codes; and sequential batch numbering.

At drupa, we are showing a solution that provides better image quality, lower costs, and the ability to add complex graphics at late-stage production. It’s called Masca ID DIGLase Powered by Xerox.

This incredible technology produces high resolution, permanent and irreversible inline digital printing using laser printing technology that is inkless at the point of printing.

Customer Signings

Many customers made investments in new technologies and workflow offerings during the first week of drupa. Here is just a sprinking:

- Hume Media in Ontario, Canada, purchased a Brenva HD Production Inkjet Press to increase competitiveness when printing books exceeding volumes of 1,000

- DocOne became the first to invest in the new Xerox Trivor 2400 Inkjet Press. In fact, they purchased two. As an aggregator of up to 250 million pieces of mail for nearly one billion digital printed pages per year, the new Xerox Trivor 2400 Inkjet Presses will help DocOne deliver higher quality materials to their customers, providing the company with flexibility and scalability as business demands increase.

- Galahad Management Services, which purchased a Xerox Trivor, specializes in direct marketing for the international market. Already with a Xerox iGen 5 Press and Xerox Impika Compact, they view the Trivor as an asset for handling personalization and large quantities.

- MailaDoc Ltd., a UK-based firm, purchased a Xerox® iGen® 5 with Xerox FreeFlow Core and a second order for XMPie StoreFlow Pro. The iGen 5’s fifth colour option and industry leading automation features from FreeFlow Core and StoreFlow Pro will allow the company to broaden their business opportunities and also enter new markets.