No opportunity is brighter than inkjet. And the numbers clearly back it up.

According to InfoTrends, production color inkjet accounted for 42% of total production digital color volume in 2014, globally. By 2019, that number is expected to raise to an astonishing 57%.

Inkjet brings to a higher volume band all the advantages of digital printing – including personalization, electronic collation, just-in-time manufacturing, workflow automation, high-speeds and productivity – to key applications pegged as growth opportunities, such as books, catalogs, direct mail and transactional documents.

But while inkjet has clearly represented the future of production color for quite some time, what hasn’t been clear is what’s stopping so many printers from getting their hands on the technology.

The reason? Because, historically, only the largest print shops have had the high volumes, deep pockets and available floor space required to justify seven-figure inkjet acquisitions.

Fortunately, those times are changing.

Enter the Zone of Disruption

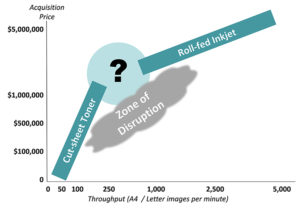

It’s a common predicament faced by many print shops: Tasked with large volumes, do they sacrifice productivity and cost-per-page economics to place jobs on toner devices, even if run lengths make it a less than ideal fit? Or do they evaluate the transition to continuous feed inkjet, even if they don’t quite have the volumes to justify the

investment?

The void that sits between these two volume bands is referred to as the ‘Zone of Disruption’ by InfoTrends, a largely un-served space where few solutions exist above high-volume cut-sheet xerographic presses and below low-end inkjet presses.

To qualify as a ‘disruptive’ technology in this space, InfoTrends says the product must carry a capital acquisition cost of less than $1 million, offer very competitive running costs and hit high levels of productivity. This puts them at speeds faster than current cut-sheet color toner devices, while at a capital acquisition cost lower than most 20” roll-fed color devices.

Last year, we debuted the Xerox® Rialto® 900 Inkjet Press as an entry-level solution to entering inkjet, featuring an integrated roll-to-cut-sheet design that helps it fit on any size production floor.

Now, the zone has a new resident: the Xerox® BrenvaTM HD Production Inkjet Press.

Breaking the Mold

Traditionally, the most successful high-speed inkjet machines have been roll-fed. In designing this press, however, we chose another route. Rather than fitting between cut-sheet toner and roll-fed inkjet systems, we decided to combine the best of both – into one press.

Building off of our heritage of innovation – and borrowing from trusted technologies such as the iGen, Nuvera and Impika – we created one of the first hybrid cut-sheet inkjet presses on the market.

The result?

The Xerox® BrenvaTM offers productivity, ease-of-use, and affordability – all while falling well under the million dollar price point and fitting into an extremely small footprint.

But acquisition costs are just one part of the equation. Because it relies on inkjet technology, the press’ run costs are low. That’s what makes low coverage applications like transactional documents a perfect fit for Brenva. And because it has a cut-sheet design, stock changes and jobs that require more than one type of paper are a snap.

https://youtu.be/iXzCqfalFeA?list=PLioPSVdbzdpZHN7MyCsEnX76Y18cS-34X

Flexible Options and Built-in Intelligence Deliver Consistent Quality.

With its cut-sheet design, Brenva gives you a whole new level of flexibility. The press features up to eight different paper drawers, a sheet capacity of up to 20,000 and the ability to handle 60 to 220 gsm jobs. Plus, a K-only mode means you can move between applications such as mono books and full-color direct mail with the click of a mouse.

And while the stocks you run can easily be varied, the quality is always constant.

An in-line spectrophotometer ensures consistent color quality while automating the time-consuming color calibration and profiling processes. And with real-time detection and correction, Brenva automatically makes corrections to missing jets, ensuring clogged nozzles don’t cause unexpected quality issues. The press can also vary drop sizes to ensure the best quality at the lowest cost.

That’s the benefit of combining two great technologies into a single hybrid press—you get all the capabilities and benefits packed into one device.

If you want to read more about the Xerox® BrenvaTM HD Production Inkjet Press, check out the white paper from InfoTrends, “The Value of Cut-sheet Inkjet.”