Written by Howie Fenton

Senior Technology Consultant, NAPL

Earlier this year I worked in Pittsburgh and stayed very close to my old stomping grounds near the former GATF (Graphic Arts Technical Foundation) building on Forbes Ave. Passing the iconic building reminded me of all the years of training classes we offered, especially the Graphic Arts Orientation program.

Like everyone else, I had to learn to teach different modules in the course and I was particularly fascinated by the role of moisture in paper. I would have never guessed that the fibers in paper store humidity and could affect printing quality and digital press jamming.

Moisture in Paper? Yes, paper is hygroscopic. This means it picks up moisture from its environment and it will release moisture into the environment to try to reach equilibrium with the moisture in the air. Moisture content is important in inkjet, laser, and offset printing. The first thing to understand is the importance of purchasing and using paper with the right moisture content. The second thing is to try and maintain stable moisture content with your paper handling to try to work within the recommended specifications.

The moisture content is measured as relative humidity and it affects the amount of moisture in paper. Typical, paper is produced to an absolute moisture content between 4.0 and 6.0%, meaning 4 to 6% of the paper’s total weight is made up of water. But once unpacked, the paper can either absorb or dissipate moisture. Most papers are designed to be stable in a 45-55% relative humidity (RH) at 72°F environment.

Different printing processes work best with certain amounts of moisture. In digital printing, the moisture content can affect the toner adhesion, paper jams and the fuser roller temperature. In offset, it can affect the interaction between the ink and the press, the paper and the press, and the ink and paper. Inkjet is affected by many of the same issues, but is even more susceptible to dot gain or ink spreading, drying delays, and ink show through. Here are the typical recommendations for the moisture content for different printing applications:

- Laser grades: (4.5%) – Less moisture, less reaction to fuser heat

- Pre-printing: (5.0%) – When printing both offset and digital, you need less moisture then offset alone but more than just laser

- Offset grades: (5.5%) – Higher moisture, less reaction to fountain solution

The effect of moisture on paper is nothing new. In fact, one of the best seminars on this subject was offered in 1927 by Helen Kiely, the Chief Chemist at the American Writing Paper Company.

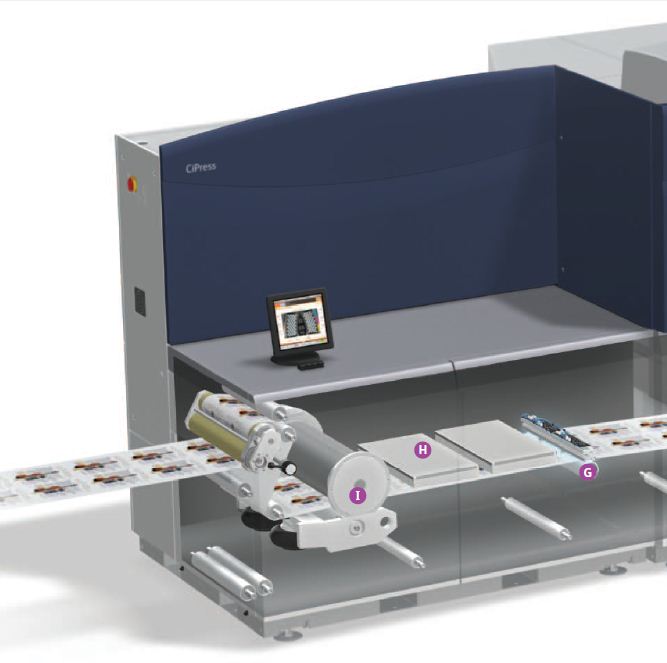

What is new are the newer printing technologies (high speed laser and inkjet) and the effect of moisture content on the paper transport, toner adherence, and quality due to the absorption of inkjet inks and inkjet papers.

Paper Handling Best Practices

The same basic paper handling tips created for offset printing are also valid for newer printing technologies. They include:

- Store the paper in a room where the temperature and humidity are controlled. If that is not possible, leave the paper in the room that it will be printed in for 24 hours.

- Keep the paper shrink wrapped and away from outside walls.

- Before you remove the wrap, make sure that the paper is the same temperature as the surrounding air.

- Keep your production space between 45 – 55% RH, temperatures constant and near comfortable conditions.

- Watch outside doors for moisture loss/gain, especially from loading docks and consider installing a second barrier such as plastic or forced air between the docks and production areas.

- Acclimate the paper after printing to allow moisture return (offset, laser) or “outgas” (inkjet)

Do you have standard paper handling processes? Are they effective? I’d love to hear your feedback!

—

Howard Fenton is a Consultant and Business Advisor at NAPL. Howie advises commercial printers and in-plants on benchmarking performance against industry leaders, increasing productivity through workflow management, adding and integrating new digital services, and adding value through customer research.

Dear sir,

I am a graphic arts consultant involved in the import & system integration of used prepress, press and packaging machinery in India. Now, there is a discussion on Direct Imaging. Though, it is very late to discuss with customers on the likes of toner, electric inks made available for HP Indigo, Xeikon, Xerox, Konica, etc.. is there any study, you have made on dry offset technology’s performance in hot tropical conditions like India ? As dry offset performs well in USA/Europe/Canada as 6 months in a year being cold and during summer, it is not hot as India going through 10-11 months in a year. So far, I have never seen dry offset working in Asian countries. If you have made any study on direct imaging and your prediction of its future, it would benefit the industry. Regards,

Hi Kondas –

Thank you for reaching out and providing this excellent insight. While I do not know of any research/studies off the top of my head that satisfy what you are looking for, there are many industry professionals, consultants and analysts that browse these blogs. Hopefully a community member has some information they can share. If I come across anything, I’ll be sure to post.

Bill (Xerox)

I am curious as to how one would go about measuring the moisture content of their paper?

Hi Tara – thanks for the comment! We will be reaching out to you via email to provide some additional information on this.

Thanks again,

Jacob (Xerox)

Printer would not feed. After becoming very frustrated and crawling around on floor fiddling with printer, I finally took paper to oven and set oven at 200° and left paper for 30 minutes. Works just fine with dry crisp paper!!!!!

I’ve always understood that a page heavy with grahpics/color will impact the copier, and possibly gum it up. However, I cannot find any reference to this idea on the internet.

[…] to expert Howie Fenton, “paper is produced to an absolute moisture content between 4.0 and 6.0%, meaning 4 to 6% of the […]