For the last two decades, digital color presses have advanced by continuously improving offset-like quality while adding value with digital’s faster turnarounds, lower-cost short runs and variable information printing. This innovation path continues to have runway, evidenced most recently by emerging developments in metallic inks. New digital solutions offer the promise of producing metallic images rivaling those of traditional processes, while delivering all of digital printing’s advantages.

For printers, this presents an opportunity to generate new revenues with high-value applications that expand and differentiate the shop’s offerings.

Production of metallic images has long been the exclusive realm of analog processes using offline foil stamping, offset metallic inks and foil papers. Digital technologies add value to metallic applications in several ways:

- Low-cost short runs and variable information printing with metallic inks present brand new, potentially lucrative opportunities to explore.

- Fast turnarounds match those of non-metallic digital printing applications, pleasing customers accustomed to the lengthy waits associated with traditional processes.

- Production costs are lower due to the elimination of custom dies, less wasteful processes, and an in-line workflow that reduces staff time and improves overall productivity.

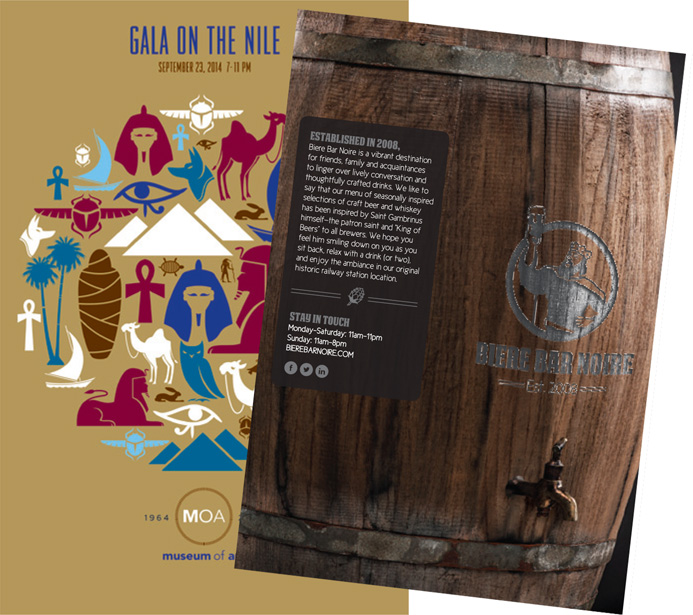

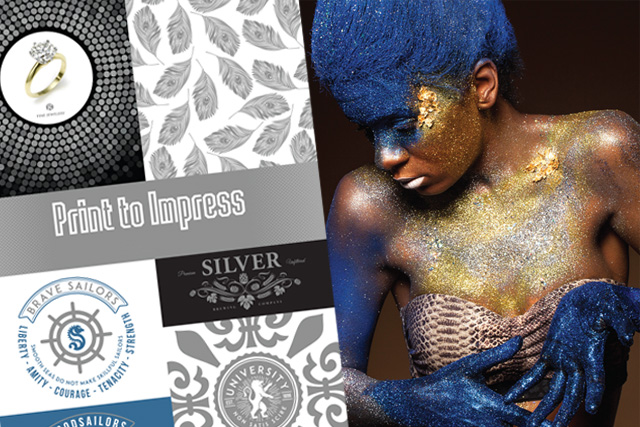

And of course, the finished product delivers the premium look your customers’ desire, enabling high-value creative effects, personalization and the visual pop that wows readers. Metallic applications that can be produced with traditional processes can be candidates for digital printing, as well as some applications unique to digital, including:

- Seals on official documents, such as certificates and diplomas

- Personalized communications, bringing the eye-catching sparkle of metallic inks to both static and variable elements in content tailored to be relevant and engaging to each recipient

- Highlighting logos, images, text and other graphic elements in a wide range of direct marketing materials, collateral, business identity items, invitations, greeting cards, posters and photo publishing products—to make them shine

- Image overlays on photos, to create a high-impact look

Product packaging to enhance the brand and attract attention

Product packaging to enhance the brand and attract attention- Menus, point of sale signage and other durable pieces produced on the wide range of digital-printing-qualified synthetic and specialty media, including vinyl, polyester, plastics, magnetics and textiles

- Creative pieces that take advantage of pre-die-cut stocks; application-specific stocks for ID cards, labels and mini photo books; as well as textured stocks and vellum

Xerox earned a 2014 Graph Expo Must See ’Em Award for its technology demonstration of metallic gold and silver dry inks for the Xerox Color 800/1000 Presses. Soon we’ll have a lot more to say about how this new capability can help you grow your business.

If you could produce metallic applications on digital presses, what opportunities would you pursue?

Comments are closed.