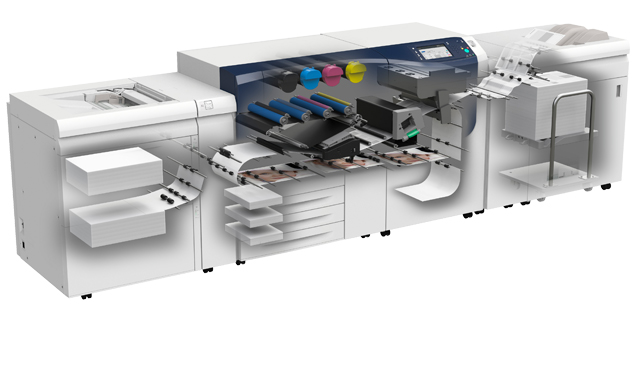

Today we are pleased to introduce the Xerox Versant 80 Press, helping to extend the versatility and performance features found in the Versant family to a production digital press ideally suited for those printing between 30,000 to 80,000 pages a month.

The Versant 80, which will replace the Xerox C75 and J75 presses, is designed to help simplify business growth and automate complicated, time-consuming processes. Fitting into many production environments, including in-plant operations, commercial print shops, and quick printers, the Versant 80 excels at delivering the highest quality – faster and more efficiently than ever before.

Let’s take a look at how the Versant 80 brings a higher level of production quality, features and functionality to a smaller footprint offering.

More Performance: Faster, Flexible and Full-Featured

In the Versant 80, you have a powerful, flexible digital press that combines walk-up simplicity with offset-quality performance. Print in color at speeds up to 80 ppm on a robust range of media up to 350 gsm. There isn’t a press in its class that outperforms its speed and color accuracy (more on color accuracy in a moment).

What’s the secret? A new Compact Belt Fuser that applies the uniform heat and pressure needed to bond toner to a wide range of surfaces without slowing production speeds…all while optimizing image quality on solids, tints and halftones and delivering faster output of mixed media jobs. This is the same compact belt-fusing system used in the Versant 2100 Press.

Need even more performance? The optional Performance Package enables the Versant 80 with more automation (an inline spectrophotometer automates color calibration), more quality control (complete with Automated Color Quality Suite, available only to the Versant 80 Performance Package) and the ability to maintain top speeds of 80ppm on all media up to heavyweight 350gsm.

Need even more performance? The optional Performance Package enables the Versant 80 with more automation (an inline spectrophotometer automates color calibration), more quality control (complete with Automated Color Quality Suite, available only to the Versant 80 Performance Package) and the ability to maintain top speeds of 80ppm on all media up to heavyweight 350gsm.

Quality that’s Easy, Accurate and Automated

Achieving top-notch image quality is easy, accurate and automated with the Versant 80 – complete with Ultra HD Resolution (a Xerox-exclusive technology), push-button easy front-to-back registration, color automation and more. Let’s dive right in.

Ultra HD Resolution: What is it?

Just as the picture on your high-definition television is only as good as the input it receives, the quality of output on your press is only as good as the RIP data it receives. The Versant 80 achieves unprecedented results by combining 2400 x 2400 dpi imaging resolution with up to 1200 x 1200 x 10-bit rendering resolution. That’s four times more pixels than the Press standard!

By rendering at a higher DPI, Ultra HD Resolution (referred to as Ultra Smooth Gradients in the Fiery workflow) preserves fine details in graphic fills, continuous sweeps, line art and text. The more pixels moved by the RIP to the print engine, the more detail that makes its way to your customer’s hands.

Learn more about Ultra HD Resolution by downloading InfoTrends’ White Paper, titled Advances in Imaging to Improve Output Quality.

Delivering Higher Quality with Less Operator Involvement

“We were overwhelmed with how well the Versant 80 matches Pantone Matching System colors. Prior to this press, we had to manipulate the color, but with the Versant 80 we just select a spot color and it hits it right on – the first time,” said Betsy Allen, owner, Cortland Press & Carbon Copies.”

The Versant 80 has Closed Loop Process Controls built right into the press, which translates to more quality and less operator involvement.  Essentially, the press monitors itself, continually checking quality and making adjustments using color and density patches and sensors.

Essentially, the press monitors itself, continually checking quality and making adjustments using color and density patches and sensors.

Another automation feature found inside the Versant 80, Simple Image Quality Adjustment (SIQA), takes the guesswork out of perfect side-to-side and front-to-back alignment with sophisticated laser technology that generates dozens of reference points to account for paper surface anomalies, changes in humidity and other variables.

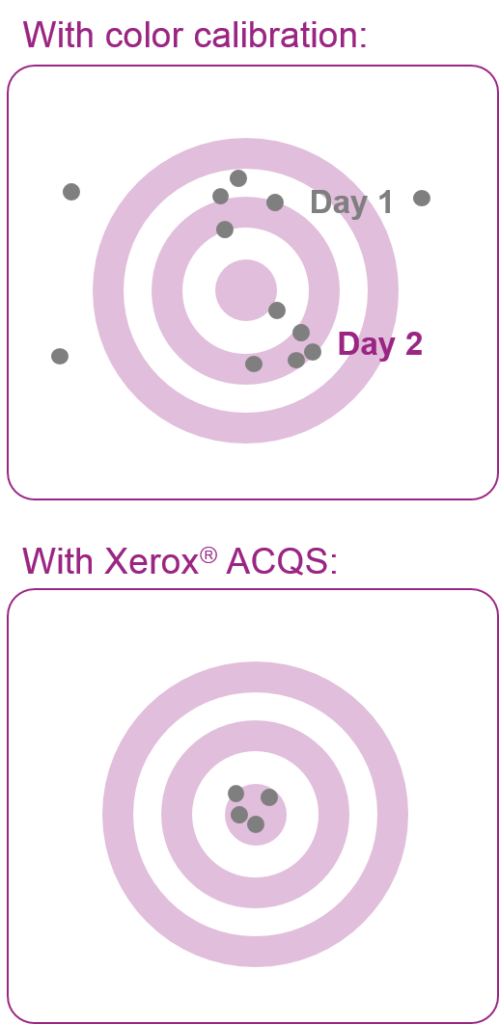

Your customers demand color consistency on most, if not all, of their jobs. Achieving this requires color calibration. When performed, it can deliver stability and consistency on a short-term basis, but it can be difficult to maintain long-term accuracy. It’s also time consuming and diverts your press operators from focusing on other critical production tasks. Xerox Automated Color Quality Suite, included with the Performance Package, uses automated on-press calibration and profiling to help you effortlessly match approved proofs and previously printed jobs.

Want to Learn More?

Watch the replay of our Gogle+ Hangout: Looking Beyond Dots per Inch with the New Xerox Versant 80 Press. Hear from two early adopters of the Versant 80 technology, Betsy Allen, owner of Cortland Press, and Tim Sheppard, production director at Alphaset Digital, as they share their experiences. Jim Hamilton of InfoTrends also led a discussion on the important role played by spatial resolution, tonal resolution, digital front ends and substrates in high-quality digital color printing.

Customer Review: Cortland Press on the Xerox Versant 80 Press

Cortland Press, a family owned print shop in Cortland, NY, needed their next digital press to deliver quality, value and reliability – all wrapped into a small footprint. Watch their story and hear their experiences using the Xerox Versant 80 Press.

[youtube]https://www.youtube.com/watch?v=FEmZ6KAUhzg[/youtube]

Still Looking for more?

Looking for more video content highlighting the key features, functions and innovative technology found inside the Xerox Versant 80 Press? We’ve got you covered:

- Product Tour of the Xerox Versant 80 Press

- Overview of the Xerox Versant 80 in 1 Minute

- Ultra HD Resolution

- Closed-Loop Process Controls Deliver Better Image Quality

- Simple Image Quality Adjustment (SIQA) Overview

- Image-to-Media Registration with SIQA

- Density Uniformity Adjustment with SIQA

- Image Transfer Adjustment with SIQA

- Custom Paper Settings