Written by Laurie Riedman, a Xerox Contributor

Last week I took a tour of a “green” house of sorts. Yet, this wasn’t your average greenhouse. Unlike its down-to-earth cousins that grow live plants and flowers – this “green” house is a $120 million dollar manufacturing facility – only a handful of its kind in the world – that is quietly growing – yes I said growing – an energy efficient toner for Xerox.

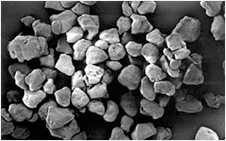

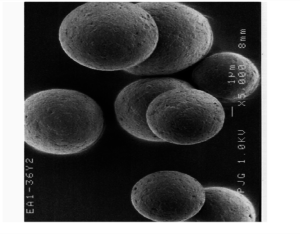

EA toner is unique in that it is literally “grown” from chemical nanoparticles, resulting in the uniformly sized, shaped and structured particles that can be more precisely controlled resulting in crisper lines, images and text. In contrast, traditional toner is created by physically grinding composite polymeric materials to micron-sized particles requiring a high level of energy and resulting in toner that is inconsistent in shape and size.

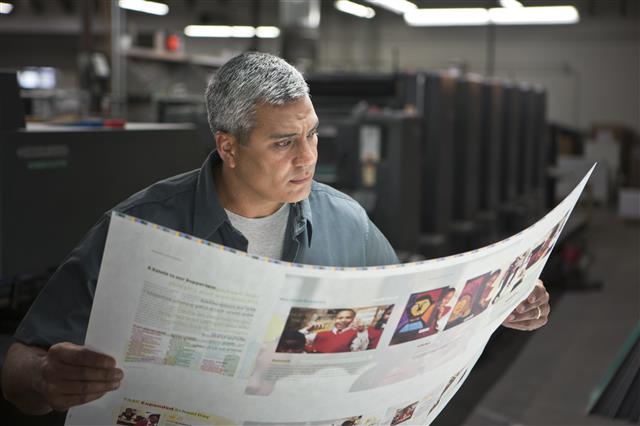

During my visit, I walked past a portion of the more than 29 miles of pipe and the over 100 giant shiny stainless steel tanks (where the toner is grown) getting a glimpse at the proprietary and extremely innovative manufacturing process of EA toner that uses less toner per page while providing sharper image quality, improved fine-lines and text, high reliability and faster warm-up times.

Developed by Xerox and protected by more than 300 patents, EA toner is used in over 50 Xerox office and production printing products. Compared to the conventional process of producing toner, manufacturing toner by the EA process requires 30 – 35% less energy per pound of toner made.

According to Info Trends, between 2013 and 2018 production digital color toner-based pages will grow at a 6.2% compound annual growth rate, amounting to 295 billion pages globally by 2018, which presents a sizeable opportunity for the chemically grown toners used in Xerox production devices.

To keep pace with the demand for this innovative toner –– Xerox just this week cut the ribbon on a plant expansion that will increase manufacturing capacity by 40 percent.

The expansion increased the plant size from 100,000 square-feet to 155,000 square-feet and added 54 new jobs and about $26 million in EA toner manufacturing equipment.

The $120 million dollar plant opened in 2007. Among the pipes and tanks I have already mentioned – the plant features nearly 11,000 sensors that track information and temperature, humidity, air flow and other variables to ensure the toner is grown to the specific shape, size and structure.

After touring the new expanded plant and meeting with the scientists, lab personnel and plant staff who help grow the toner and maintain the sophisticated toner-growing machinery – I’d have to say that this expansion provides growth for Xerox in more ways than one!

To learn more about EA toner – read this white paper and watch this video.

—

Laurie Riedman owns Riedman Communications, is a geek at heart and loves working with Xerox scientists around the globe. When she isn’t talking to media on behalf of Xerox or her other technology clients, she is cooking and baking up a storm feeding family, neighbors and friends.