There’s a funny story told by the former iconic football coach John Madden after he attended an 8 hour clinic given by legendary Green Bay Packers coach Vince Lombardi. As the story goes, Madden, at the time an up and coming coach, was shocked when he sat down and listened to Lombardi speak for eight hours about one play, the famous Packers power sweep. When Madden tells this story he admits he walked in thinking he knew everything and walked out realizing he knew nothing.

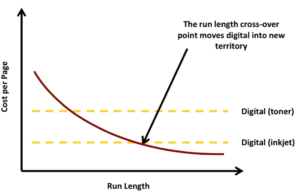

I don’t know about you, but there are very few subjects I’d want to listen to for that extended a period of time. But one subject that is becoming more important and maybe worthy is cross-over analysis. The cross-over analysis shows the crossover point where one printing technology becomes less expensive than another printing technology.

This is not a new subject because we have been calculating crossover points between toner based printing and offset presses for years. But there is a renaissance of interest as less expensive inkjet presses come to market and we try to predict which applications will become better suited to inkjet printing.

Just as Madden learned that there is more to the Packer power sweep, we are learning that there’s more to the crossover analysis then most people realize.

Here’s a few lesson learned:

- Not all crossover points are the same

Different products have different crossover points, meaning that a box of business cards will have a different curve than a box of student course packs. The dimensions of the products obviously plays a role, but finishing can play a much larger role and in line finishing can play an even more important role.

- Not everyone calculates the crossover point the same

It’s not unusual to calculate crossover points based on running costs (paper, toner, clicks), but this can result in significantly different crossover points then when you calculate the total cost of operations. This has become especially important lately with the advent of multi-million dollar inkjet presses and million dollars finishing solutions.

- Unique Inkjet Issues

One of the toughest elements to estimate is inkjet print coverage. In fact, the best way may be to assume different coverage amounts, such as 5%, 15%, 30% and create different curves. It gets more complicated when you have to factor in paper options (untreated, pretreated, sprayed on agent) and different measures of ink barrels, grams or liters of ink, etc.

- Not everyone understands the full impact of utilization rates

One of the ongoing debates in the printing industry is the strategy of offering lower prices for higher volumes. Experts can argue for hours about the merits of each. But what is rarely discussed is the impact of greater utilization on the costs of manufacturing. There are critical volume bands that can significantly reduce manufacturing. For example, for a certain class of toner devices, increasing volumes from 450,000 pages per month to 900,000 pages per month can reduce manufacturing costs from $0.25/page to $0.125/page.

- Power Consumption can play a role.

While toner and inkjet devices both consume electricity, some devices can use much more. The levels of consumption can even vary among inkjet presses. Some use up to 195kw/her while others use only 40 to 50kw/her. This could significantly impact the utility bill and/or require special upgrades such as installing new lines, transformers and additional HVAC.

- Miscellaneous.

While both toner and inkjet presses require unique installation and recycling efforts, the high speed webs often require more. The barrels of ink may require plumbing. Some require recycling, some are permanent, and others are refillable with smaller/cheaper containers. Some inkjets need thermal circulation of liquids for heating and cooling that require stand-alone HVAC systems. Many also require the exhaust to be vented. In some cases, the ink containers may be larger and thus requiring forklifts.

Bottom line: If you’re considering the purchase of an inkjet production press you might want to master the crossover analysis to determine which of your existing products are best suited and which new products you could introduce using an inkjet production press.

—

Howie Fenton is Associate Director of Operational Consulting at InfoTrends. For 25 years, he has worked with in-plants and commercial printers on: benchmarking operational and financial performance, recommendations to increase productivity/reduce costs and strategies to increase value.To email click here.

Comments are closed.