Do you suspect that production makes too many mistakes? Do you cringe when you hear “We had a problem and had to re-run a job”? Have you ever seen a month’s worth of profits wiped out by a single mistake?

If you answered ‘yes’ to any those questions then this blog is for you.

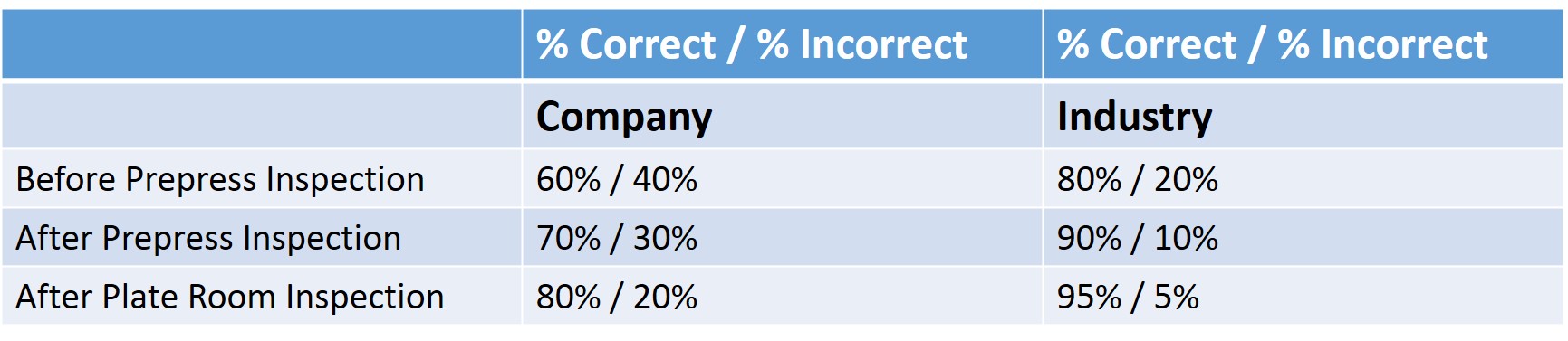

In previous blogs we have discussed process control and rework. But as far as we know, no one has ever attempted to benchmark errors caught in three consecutive quality control checks in prepress and the plateroom. For a recent assignment we had to compile data from different companies resulting in this first attempt.

Over-Inspection Is Not Good.

The term “Before Prepress Inspection” refers to errors caught in preflight and prepress before work is imposed. The expression “After Prepress Inspection”, refers to errors caught after imposition but before plate making. Lastly, the expression “After Plate Room Inspection” refers to errors caught after plates are made but before they are mounted on the press.

There is a strange phenomenon we see in some companies that we call ‘over inspection’. We would define over inspection as having multiple people looking for the same mistakes in several consecutive steps and not catching them. The motivation for over inspection is always the same, there are too many mistakes, discovered late in the process costing the company money and jeopardizing customer relationships.

The root cause analysis often results in four reasons:

- Communication errors between staff.

- Lack of standard operating procedures.

- A culture of hurry up, get it done, do whatever it takes.

- A lack of process control to ensure that errors are avoided instead of caught and repaired.

Ironically, one would assume that companies using the most inspection steps would result in the least errors. But just the opposite is true. Companies with the highest rework often create exorbitant inspection procedures and long checklists for multiple production steps, because they don’t make it right the first time. If this sounds familiar, then you may want to consider a process or quality control initiative.

—

Howie Fenton is the Vice President of Consulting Services for IMG. He helps with in-plant and commercial printers measure, identify and overcome operational issues. To learn more about measuring performance, benchmarking to leaders, increasing productivity, and improving your value e-mail hfenton@imgresults.com.

Yes I agree that we over inspection