While walking around a previous trade show, I was shocked to find a fellow competitor using a Xerox sample to show their finishing capabilities on a new press they launched. Their inline finisher wasn’t working, so they thought it would make sense to visit the Xerox booth, take our samples and use them during their demo…and sure enough, on the back of the sample it said “Printed on a Xerox Nuvera 288 Perfecting Production System”.

I don’t blame them for choosing to show a Xerox sample when they were in a time of need. My concern was if they were misrepresenting capabilities of their new press.

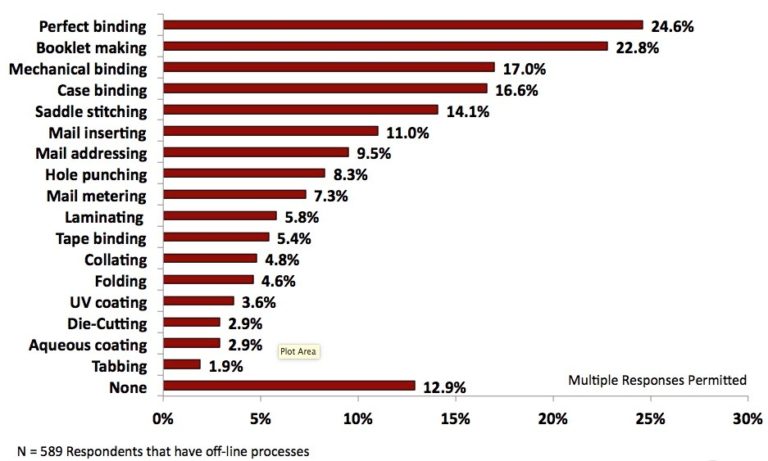

My point with that brief story is that there is a lot of smoke and mirrors out there. So when considering an inline saddle-stitcher for your digital press, ask plenty of questions and pay attention to the following when evaluating its finished output and specifications:

Staple Placement

If the staples aren’t positioned properly, crossovers within the spreads may not match up correctly. This can make a booklet look flawed and unprofessional in appearance. Staples should be positioned right on the score and fold lines, and folded completely flat to protect readers’ hands from nicks. The best option is a saddle-stitcher that gives you flexibility to adjust the staple, score, and fold locations on the fly.

Sharp, Clean Folds

Scoring weakens paper fibers by indenting the fold lines. This helps prevent toner cracking on heavyweight stocks, maintains image integrity, and allows sheets to fold flatter. Make sure to always check for scoring capability if a saddle-stitcher runs heavyweight stock.

Neatly Trimmed Appearance

When a finished booklet has several sheets, the inside pages “creep” or extend further out than the outside pages. Prepress software can take this phenomenon into account and finishers with face-trimming capabilities produce a more consistent and professional looking book by trimming the ragged edges off. A saddle-stitcher may fold and staple up to 50 sheets — but if it doesn’t trim— you are going to have one very ugly looking booklet.

Full-Bleed Color

By trimming the head, face and foot of a booklet, you produce the full bleed effect that allows images and color to cover the entire finished page. This opens up many opportunities for graphic designers to make your finished document stand out in a crowd. I’ve had trimmed and untrimmed booklets sitting on top of my press at a show and the trimmed booklets are always the first to be picked up and taken away.

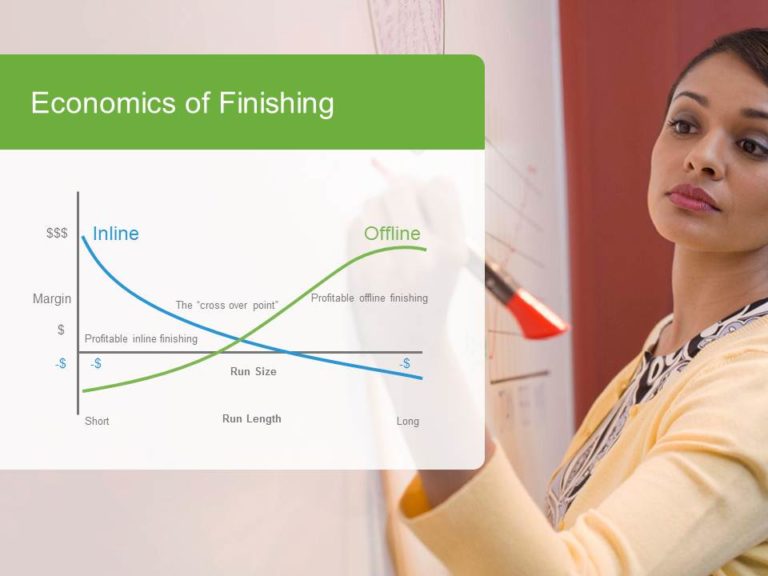

There are many other factors that come into play when purchasing an inline finisher. Can it run in an offline mode? Is it truly meant for production volumes? How does it handle trim waste? Can I feed in sheets from another job? And most importantly, was the sample I’m holding finished using this equipment?

2 Comments

Comments are closed.

Good points here.

A couple others are worth remembering. Size matters. Will the finishing system handle the largest possible pages your press can produce? How easily are the devices adjusted to accommodate different page sizes?

How does the throughput of a device align with that of your press? How might you need to adjust your production planning to optimize the speed of both devices?

these are really nice brochures. the colors are bright and very attractive to the eyes, which means that it can also attract prospective clients.