Written by Joel Basa

e-Marketing Manager, Xerox Corporation

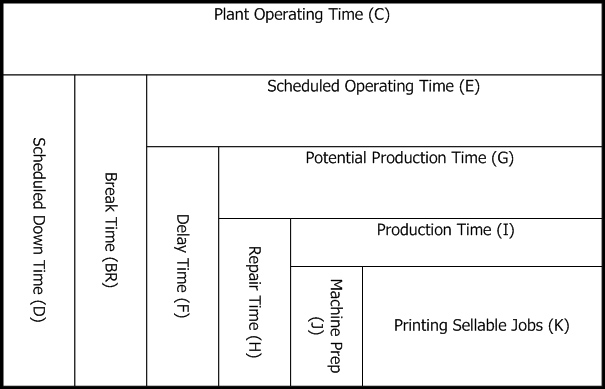

Impressions per hour. Pages per minute. Sheets per hour. The industry has various ways of describing printing speed. However, let me ask you, “How productive is your press (digital or non-digital)?” If you’ve responded with a phrase similar to “120 Pages Per Minute” or “7000 Impressions Per Hour” then I’ll repeat my question, “How productive is your press?” Is the concept of “productivity” equivalent to “print speed?” I would argue not.

Step back and think about the printing process. Simply put, the objective of anyone operating a press is to produce output that will meet your customers need…something you would sell to them, a sellable print. It’s a manufacturing process. However, as we all know, the process of producing prints rarely goes without challenges. A press may produce inconsistent color, streaking, skewing and many more challenges that would result in disruption to the print process.

If a machine is capable of “X impressions per hour” the more important question to ask is, “how many sellable prints are produced per hour?” Some may call this “Operational Prints Per Hour.”

What are the things that negatively affect Operational Prints Per Hour? Just like in traditional manufacturing: defects and downtime. Let’s take a look at a couple challenges you may be facing as you produce work for your customers.

Color: Customers demand accurate color and consistent color. Have you had to interrupt jobs in order to make adjustments to color? These adjustments affect the true productivity of your shop. Does your press provide color management automation to some of these adjustments?

Streaking: Non-sellable prints are often produced when a press starts producing output that contains streaks? With a break-fix mode of many presses, the operator would have to make adjustments in order to bring the machine back to sellable print quality. Ideally, automation would be in place to detect and eliminate this problem.

I strongly feel its important for the industry to start thinking about productivity, moving away from speeds and feeds and more to what truly helps you produce more jobs and grow your business. Think about the productivity of your press. How are you measuring this?

Interested in similar topics? You may want to check out:

Comparing technology based on print quality, speed and substrate range is what all our clients do when assessing which digital press would be right for their business.

Sellable prints per 8 hr shift, per week or per 20 working days should be the key criteria. Ensure the benefits of the new technology (e.g. in-line calibration or streak detection) are highlighted against competitive presses. These advances in technology really do save time and make the process of producing sellable prints easier!

Just like the introduction of robots to car assembly line save time and make producing sellable cars easier.

Most important is to help clients with their due diligence and point out the level of maintenance a press requires to keep producing sellable prints. Some platforms require 200 – 400% more operator maintenance than an iGen4 or a Color 1000 Press over the period of 5 working days.

This can even be even higher over the average month of 20 working days. This loss production time is not captured when comparing theortical impressions per minute or impressions per hour.

The other piece of the jig saw is ease of use. If your client’s key operator is away, how easy is the press for their part time operator to jump on and keep producing sellable prints. Does he / she know all the maintenance routines?

Great topic.

Throughput (sellable units per day), use of resources (energy, water, materials, capital, labor) per unit of production, as well as errors, injuries, waste, unscheduled maintenance/repair incidents per unit of production are classic measures associated with productivity… however, there is growing pressure from groups like the Sustainability Consortium (www.sustainability.org) and investors for full cost/benefit accounting and reporting of the lifecycle sustainability aspects and impacts associated with a product.

Increasingly, many investors and leading brands are looking to lifecycle analysis and full cost/benefit accounting as a hedge against future potential risks and liabilities associated with the their supply chain activities… and some are looking to such sustainability performance metrics as a basis for competitive differentiation and value creation.

Just as it is important to look beyond speeds and feeds to what truly helps you produce more jobs and grow your business, it is equally important to look beyond measures of economic performance and productivity to what truly helps you manage risk and the creation of sustainable value.

Reliability=Productivity. If your PIJ/Xerographic engine is down more than it’s projected service time, add in the above article and people will see what employees who are customer facing deal with on a daily bases.

On the press that we are currently develping we measure Feet and Pages/impressions. So take you pick I like the article, Thank-you