Written by Greg Cholmondeley, Workflow Practice Director, Caslon & Company

2016 seems to be the year when the industry has stopped just talking about color management and started making it happen in the real world.

All the major vendors have launched solutions focused on making color management easy and affordable enough for everyone to do. It all sounds good in the pitches, but some of these solutions have been around long enough for us to hear how customers are actually using them and how real-life situations have driven new product capabilities.

Yesterday I had a great conversation with Mike Lacagnina about color management and it left me eager to hear what else he has to say at his How to Get Your Color Management under Control webinar on August 24. The last time we spoke was when I wrote a product briefing on their IntegratedPLUS Automated Color Management solution back in early 2015. At that time they had an interesting solution, but it only worked on iGens with embedded spectrophotometers. Now it works with all kinds of presses and they have customers who are really using it. For me, this is when it gets real.

First, they have customers! Mike is going to share a video showing how Jubels, an IntegratedPLUS Automated Color Management customer in the Netherlands, is using the solution. We’ll get to see how they’re using it and hear their reactions to the system. This stuff always sounds great on paper, but seeing how it handles real-life situations is invaluable.

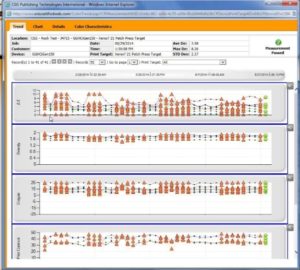

Here’s a little bac kground for those who aren’t familiar with Xerox’s IntegratedPLUS Automated Color Management solution. The objective of this solution is to provide a stable color platform across your digital color press fleet so that you can deliver consistent color quality. It’s a cloud-based solution with some unique automation capabilities that lets companies easily, consistently and centrally manage color settings on their presses. This approach makes it easier, and thus more likely, to actively keep all presses at G7 certified color consistency levels. One aspect that I really liked when I reviewed this solution is that it tracks measurements over time. This lets you identify trends or possible external influences which might be affecting quality so that you can get ahead of potential issues. Feel free to go back and view my original product briefing if you’d like to know more before the webinar.

kground for those who aren’t familiar with Xerox’s IntegratedPLUS Automated Color Management solution. The objective of this solution is to provide a stable color platform across your digital color press fleet so that you can deliver consistent color quality. It’s a cloud-based solution with some unique automation capabilities that lets companies easily, consistently and centrally manage color settings on their presses. This approach makes it easier, and thus more likely, to actively keep all presses at G7 certified color consistency levels. One aspect that I really liked when I reviewed this solution is that it tracks measurements over time. This lets you identify trends or possible external influences which might be affecting quality so that you can get ahead of potential issues. Feel free to go back and view my original product briefing if you’d like to know more before the webinar.

As I said earlier, the new version of the software now works in, what they call “near-line” mode, so that it can be used for other models of digital presses. They now sell a network connected stand-alone spectrophotometer which is set up to easily scan printed test patterns with barcodes, something Xerox calls “scan to-cloud”. The operator takes the print off any engine in the fleet, presses a button, and returns to production work that’s it. The data is automatically sent to the cloud – No PC, no USB, and no software required. Honestly, I haven’t seen this yet, but this could be a game-changer for the industry, especially for printers with satellite operations. But, like you, I have to wait until August 24.

Be sure to sign up for this free webinar to learn more from Mike about how the industry is using this new, cloud-based color management technology to manage individual presses or fleets of equipment. It’s August 24, at 2:00 pm Eastern time.

This article originally appeared on the PODi Insights Blog.