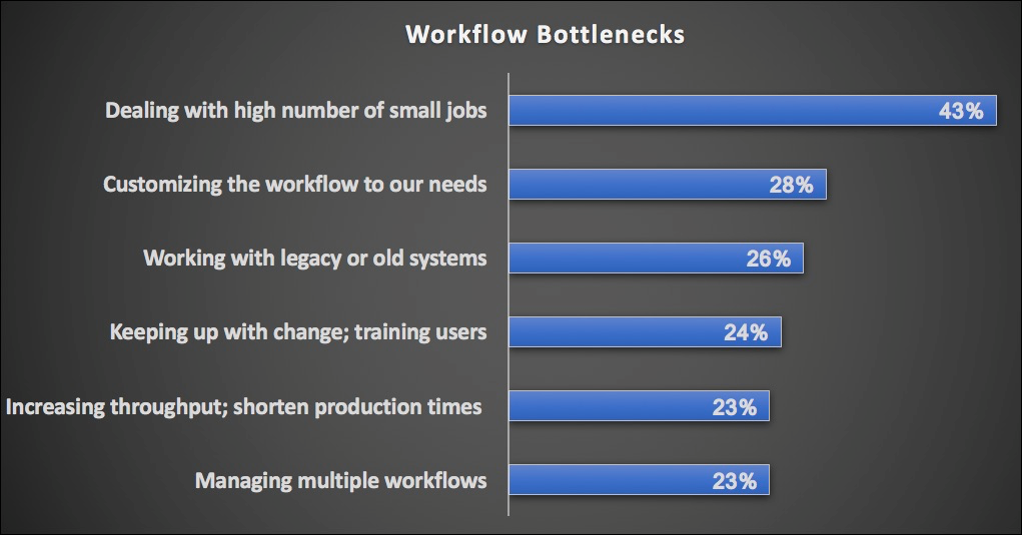

You might be surprised to learn that as we increase automation in our print production workflows, we can create new issues or bottlenecks. I was reminded of this as I read a article in the May issue of In-Plant Graphics Magazine by Pat McGrew, citing new research. The article included a chart listing workflow bottlenecks which is shown below with just the top answers.

N = 123 All Respondents

Source: U.S. Production Software Investment Outlook, InfoTrends 2017

The #1 cited bottleneck was, “Dealing with a high number of small jobs.” This often occurs after a new technology is introduced. We first saw this when digital presses created a shift from fewer and longer print run lengths to more frequent shorter run lengths. This is occurring more often as web to print workflows allow customers to reorder faster and easier with a click of a button on a mobile device or computer.

The second most cited answer was, “Customizing the Workflow to our Needs.” This can happen after installing new automate tools such as Print MIS or PDF workflow software because the company may try to use the new software like the old software which reduces the magnitude of the benefits. A better solution is changing the process to take advantage of the better workflow.

Third on the list was, “Working with legacy or old systems.” While the goal of the new tools should be to eliminate the older systems, there is often a unique product or customer that requires continued use of the old system. Sometimes this is a cost issue when the cost of one feature was considered too high for a limited usage; other times it was a detail that was missed.

Training, increasing throughput, and managing multiple workflows are next on the list. Unfortunately too many companies in the industry limit training to what is offered during the initial installation by the manufacturer. However, staff come go and new staff often miss the initial training. That is why the most productive companies reevaluate training a year after a new installation.

In terms of the “Increasing throughput” bottleneck, it is interesting to note that while software automation tools can increase productivity at one step, they often create bottlenecks in other areas. For example an e-commerce solution can automate customer service, prepress, and digital pressroom, but the additional throughput can create new bottlenecks in finishing, fulfillment, shipping, and billing. Last in this list is “Managing multiple workflows” which I think of related to the previous bottleneck, “Working with legacy or old systems”, which can be the result of a unique customer requirement or the result of incomplete “scoping” of what is needed.

Software Automation Issues

Unfortunately, new workflows almost never achieve their full potential quickly and some never achieve it. There are wide range of reasons or root causes that create gaps between the potential benefits and the actual benefits. The strategy we find most effective in identifying and overcoming these issues is called the GAP analysis. To learn more about GAP analysis you can watch on-line videos or contact us.

This is the number one request I am fixing for my clients is workflow bottlenecks. There are so many solutions and strategies that you can develop to fix these, you just need the right experts to help out.

I have a few great resources that can help out..

Brian Ruiz

Xerox Corporation

Production Color & InkJet

Program Manager

Production Printing, Software, Technology, and Business Development Consulting

Brian.Ruiz@xerox.com

(714) 310-8684

http://www.LinkedIn.com/in/BrianRuiz

Twitter: @TheBrianRuiz

YouTube: Brian Ruiz Print Expert