Written by Derrick Doi

Vice President, Quick and Franchise Print Segment , Xerox Corporation

No one knows better than print providers that business cards are not among the traditional print applications that are diminished in the digital age. For reasons that range from convenience, to lack of standards for exchanging digital business cards electronically, to opportunities to drop physical cards in fish-bowl raffles, the business card largely has retained its traditional role.

For print providers, that’s a good-news, bad-news scenario. The good news is that ongoing printing and reprinting of business cards provides a prime opportunity to probe customers about other possible work, while gaining incremental revenue.

The bad news: print providers are still printing business cards, a low-margin job that can present demanding color and registration challenges. Further, business card customers can be demanding, and rightly so, given that for many small businesses, their cards are their key sources of market visibility and brand identity. That’s a potentially volatile mix on a low-margin job where any bump in the road can wipe out profitability.

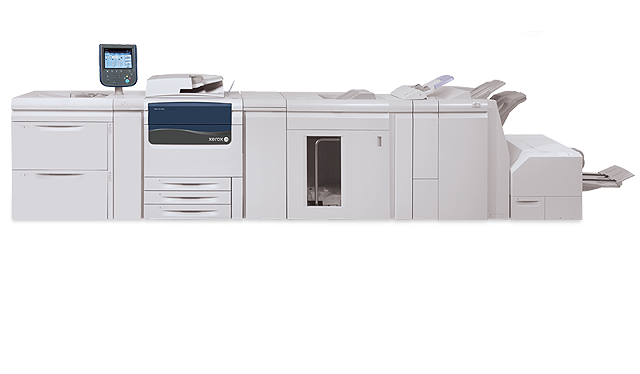

But for users of the Xerox C75 and J75 Presses, business card production can be made much simpler—provided they apply several of the presses’ powerful new automated capabilities.

[youtube]http://www.youtube.com/watch?v=Z29gdTKr-v8&index=120&list=PLioPSVdbzdpZHN7MyCsEnX76Y18cS-34X[/youtube]

Accurate Front-to-Back Registration

Printing on both sides of a business card is a popular option today, due to all the physical and electronic contact points that need to be listed as well as opportunities to differentiate with photos and QR codes. Printers can be challenged however, to align front-to-back registration.

Getting registration right typically requires operators to take measurements from printed sheets of their target media and manually enter them into a software utility. In some cases, it may even require a visit by a service technician.

But with the C75 and J75, you simply print a test sheet of the desired media and scan it with the inline scanner. The press automatically creates a media profile that adjusts for skew, magnification and perpendicularity during printing to keep front-to-back registration in alignment. Here is a video demo of the feature, known as Simple Image Quality Adjustment (SIQA).

Automating Color Accuracy and Consistency

Corporate colors need to be precisely matched on business cards and to be consistent across sheets as large as 12×18 inches—a challenge on many entry- to mid-level production presses.

Accurately representing colors begins by calibrating the press. On most entry- and mid-level digital production presses, color calibration requires printing target sheets, scanning them with a handheld external spectrophotometer that can be finicky about accepting scans, and having color management software on the press’s controller to process the results.

In contrast, the Xerox J75 has an inline spectrophotometer. Operators simply press a button to initiate an automated color calibration process that requires no color management expertise, saving considerable time and increasing the likelihood that calibration will be performed per the plant’s specified schedule. A video demo of the J75’s automated color calibration capability is available here.

To ensure consistent color across a sheet requires achieving consistent color image density—the amount of ink that is laid down. That’s a challenge for most entry- and mid-level digital presses, often overcome by trial-and-error that results in significant paper waste. To avoid the aggravation, some print providers don’t run business cards on the larger sheets that should be more cost effective, but on letter-size pages, where the right density is easier to achieve.

However, with the SIQA feature, C75 and J75 operators simply print and scan two sheets of color patches, then let the software set the proper color density, which holds for about 50,000 sheets. A video demonstration of the SIQA automated color density capabilities can be seen below.

[youtube]http://www.youtube.com/watch?v=E9nnxfYnubY[/youtube]

Automating Business Card Workflow

Once the press is tuned and the media profiled, a productive workflow keeps the job profitable. The EFI Fiery FS100 Pro Server for the C75 and J75 enables operators to program job specifications with a series of drag-and-drop operations, and to run it by simply dropping the job file into the programmed hot folder. Workflow doesn’t get much simpler than that. A video showing how to set up and use a hot folder can be viewed here.

When these automated features are engaged on the C75 and J75, production of business cards and many other print applications can be simple, fast and profitable—foolproof really.

Are business cards an important application in your print business? How do you meet the many challenges they pose? How well do you maintain profitability?