Guest post by Amy Stear, iGen Worldwide Product Marketing Manager, Xerox

More and more printers are answering the question, “How do I make money with my digital press?” by offering digital printing enhancements that can command premium pricing. These enhancements are delivered by specialty inks, and they come in two value-add flavors: those enabling special effects, such as clear inks, and those boosting quality by, for example, extending the color gamut.

Thirty percent of offset and digital promotional color pages in the United States and Western Europe receive special effects enhancements, and most are done using traditional presses and processes1. Emerging digital processes have many advantages—enabling shorter runs, faster turns, lower costs and variable information printing—but account for only about 0.5 percent of the enhanced pages1.

That’s about to change. InfoTrends projects that digital printing enhancement volume in the United States and Western Europe will grow at a 27 percent compound annual growth rate (CAGR) from 2015 to 20201. Print buyers are willing to pay as much as 24 to 89 percent more for digital enhancements than for CMYK-only printing1. And print providers can get solid profit margins that typically range from 50 to 400 percent, delivering—among other things—a quick return on the investment1.

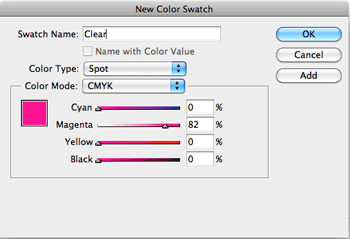

Xerox is helping print providers make the most of this opportunity by delivering specialty inks through the fifth print stations on the Xerox® iGen® 5 Press and Xerox® Color 800i/1000i Presses. And at Print 17 Xerox is expanding the iGen 5’s fifth print station palette by introducing a new White Dry Ink toner option, joining Clear Dry Ink, the orange, green and blue gamut extension colors and—in select markets—MICR. (The Color 1000i/800i offers clear and two metallics: gold and silver.)

Benchmark White Ink Performance

Xerox developed the new White Dry Ink in response to customer demand to address a range of applications in marketing, retail signage and folding cartons. It is representative of Xerox’s commitment to continue investing in new digital printing enhancements that enable new applications, add value to existing work and, for print providers, create competitive differentiation.

Even as it is being announced, the new Xerox White Dry Ink has gained industry recognition as a top performer—it won a 2017 Must See ‘Ems Award as one of the most innovative new products at Print 17. (Two other Xerox products also won Must See ‘Ems: Xerox Specialty Imaging Products and the Xerox Trivor 2400 HF Inkjet Press.)

Behind its early acclaim: a Xerox breakthrough to more than double the brightness and opacity of competitive inks for digital presses, establishing a new industry benchmark.

Achieving the benchmark benefits customers by contributing to more productive and less expensive operations. Where competitive digital presses can require four or more passes to achieve acceptable brightness and opacity, Xerox White Dry Ink saves time by requiring only one or two passes to deliver benchmark results. Further boosting productivity, a multi-pass feature on the iGen 5 enables two layers of white to be printed automatically over or under CMYK—and will provide sufficient coverage for most applications. Additional layers of white can be manually printed for custom applications in the “fifth-station-only print mode,” for special effects, such as adding even more opacity.

The Xerox approach also reduces printing costs because where other digital press suppliers charge for each printed image (click) as well as for the ink, Xerox charges only for the ink. There are no click charges for printing from the iGen 5’s fifth print station for the Clear or White Dry Ink.

Versatile and Productive

Xerox White Dry Ink plays multiple roles in the printing process:

- It enables white to be printed on colored substrates—sitting atop either non-white media or CMYK-printed images.

- It can provide a bright white base coat for optimizing CMYK vibrancy and enabling variable information printing on colored surfaces.

- It can broaden the range of non-white substrates that can be used for invitations, menus and various marketing pieces—such as direct mail, postcards, business cards and posters—often to striking effect.

- And when printed in percentages rather than full coverage, white ink can create frost or translucent effects.

Xerox White Dry Ink printing processes also have been developed to enhance productivity. In addition to the multi-pass feature:

- The time required to change the toner in the fifth print station has been reduced by as much as seven minutes under certain circumstances, improving changeover time to 18 minutes from 25. The reason: if the toner has been removed for less than four hours, a seven-minute calibration step is not necessary. That step also can be shortened if the toner has been out for four to eight hours.

- The press’s Xerox® EX-P 5 Print Server Powered by Fiery® offers a new approach to color management, the IDEAlliance G7 Calibration process, as an alternative to the Xerox Color Maintenance Tool. The G7 calibration process first achieves proper gray balance for the target media, then builds a color profile on top of that, an approach that may require less frequent profiling, according to some users.

Some White Hot White Ink Applications

The new White Dry Ink option enables a range of applications that meet customer demand while delivering favorable profit margins. Some examples:

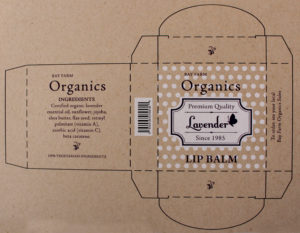

Folding Cartons—Kraft (tan-colored) and dark folding carton board are more functional and attractive with White Dry Ink. For this carton, the automatic multi-pass feature enabled one pass of White Dry Ink to be followed automatically by CMYK printing, completing the image. Much like the iGen 5’s Clear Dry Ink option, White Dry Ink is optimized for spot applications such as those on this carton.

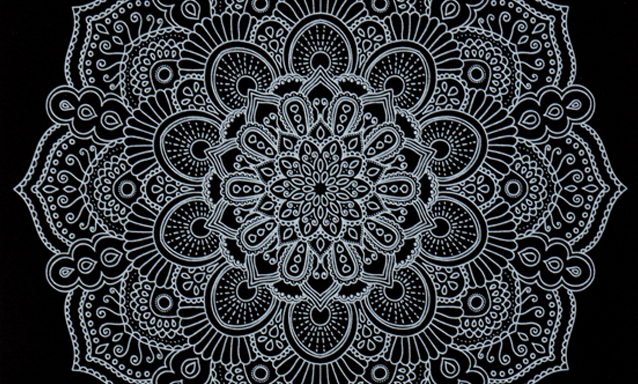

Direct Mail, Invitations, Postcards…— Using White Dry Ink with dark cover weight stocks opens up a world of opportunities to create striking designs. The automated multi-pass feature enabled two passes of white ink and a third pass of CMYK to run automatically on this deep red card stock. The iGen 5 accommodates stocks up to 18pt / 130lb cover / 350gsm—and up to 24 pt. / 610 microns with the optional Thick Stock Kit.

Varied Opacity Levels—Manually printing an additional layer of White Dry Ink can increase opacity. For this folder, the horse and text were printed with a first layer of white. The text was then manually printed with a second layer of white to make it stand out brilliantly against the black cover stock. The image of the horse received varying percentages of White Dry Ink to show the effects of shadow and light.

Clear Vinyl— White Dry Ink brings new design possibilities to transparent substrates used for retail window signage. For this sign, the automated multi-pass feature was engaged, printing the CMYK image first with white areas knocked out, followed automatically by a white backdrop.

Place Your Orders Now

The new White Dry Ink will be available for installations on Oct. 2, 2017, with order taking beginning at Print 17 in Sept. 10-14. Please check with your local sales representative regarding availability in your region.

You can learn more about Xerox White Dry Ink by contacting your sales representative and by clicking here.

-

InfoTrends, “Beyond CMYK: The Use of Special Effects in Digital Printing,” 2016

[…] tecnología white dry ink de Xerox iGen5 ha obtenido el reconocimiento de la industria como una de las más innovadoras y de […]