There’s no denying how much the inkjet market has changed in the last few years. It has come so far, so fast that it’s probably an appropriate time to step back and ask: Is it a cost effective printing solution? Does it deliver ROI?

Maybe the best place to start the discussion is around the cost to acquire an inkjet printer. Obviously, there is an initial capital investment. It is lower than some devices, higher than others. But what device is it replacing? Or, perhaps we should say, what devices? Often, a single high-speed continuous-feed inkjet printer can replace several less capable machines.

What capabilities does it make possible that weren’t possible before? Increased speed and wider media latitudes open up new opportunities for jobs that used to go elsewhere. And there are whole new areas of revenue that aren’t possible with an offset solution, as profitable as they may have been for you over the years. More on that later.

But that initial acquisition cost is really an initial investment…in growth. That’s a plus.

But ROI also is a function of minuses—reducing costs throughout your operation. For example, our waterless ink technology prints on plain paper to make the cost of day-to-day operation more affordable.

Do I buy the diesel engine with the corresponding higher price for fuel but higher day-to-day miles per gallon? Or do I opt for the gas engine, which might get slightly fewer miles per gallon but costs less to fill? We can’t answer that question for you. We can, however, offer a range of technology so that we can partner with you to provide the answer you need to be able to answer your customers’ demands.

With an inkjet solution, other things are reduced as well. Turnaround time is one. Work in progress is another. And waste. And labor. Consider that the traditional way of doing things has always called for thousands of preprinted offset shells to be printed and stored until a small amount of personalized information was added digitally. Jobs require multiple passes and multiple people. Because jobs take longer, they often sit partially complete, paid for by you, but not generating revenue. And to make sure enough of the offset shells are on hand to compete a job, a percentage are often unneeded and thrown away.

All of those are reduced with an inkjet solution. One day. One person. Virtually no waste.

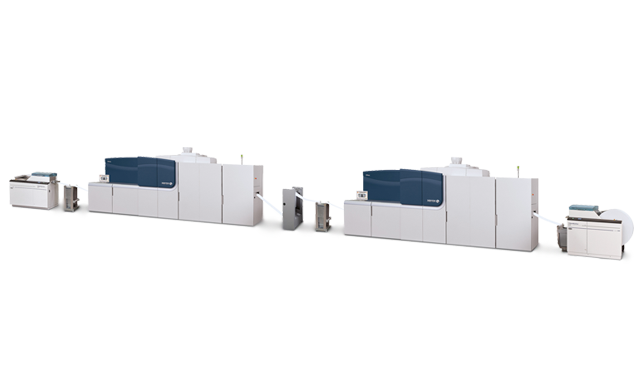

Which brings us to perhaps the biggest consideration of all. Productivity. It’s the game-changer that can make the ROI decision a virtual no-brainer. Right off the bat, the high speeds of solutions like our CiPress or Impika family of printers allow you to produce more in a shift, a day, a year. It’s an ever-present truth, not only about print, but about every kind of manufacturing. Produce more in a finite amount of time, and the costs come down. It’s true in every business, but nowhere more than ours. It’s that calculation that happens multiple times a day—is this job best produced digitally or offset?

That in itself makes the ROI of inkjet attractive, particularly if you are in the offset business and considering adding digital to your shop floor. Jobs that used to straddle that line between offset and digital now fit perfectly into the digital inkjet side of your business and contribute to its ROI.

So far, that’s everything you would expect in a discussion of ROI. But let’s take a slightly different look at a “return.” With a digital inkjet solution, personalization goes to another level. Rather than just the simplest levels of variability, virtually everything can be tailored to the recipient. And the results can be revolutionary. Response rates are often orders of magnitude higher than with a static printed piece.

Consider CW Niemeyer, who used a Xerox CiPress 500 Production Inkjet System to digitally print 500,000 catalogs with a complex personalized front and back covers featuring targeted offers according to previous buying patterns. Customers who typically shop for fashion saw clothing images while customers who shop for housewares saw furniture. The results were dramatic, generating four to five times more revenue than static covers.

But even a personalized piece becomes static after it’s printed. Digital inkjet solutions have the unique ability to link print to the Web so that content, and your relationships with customers, remain fresh. Through the use of techniques that belong to digital alone, such as personalized URLs and QR codes, inkjet can continue to drive higher response rates in marketing campaigns and transactional statements as the years pass.

Factoring that into a calculation of ROI—with the huge pluses of added revenue and the “positive minuses” (if there is such a thing) of reduced labor, waste, storage, etc.—makes digital inkjet something worthy of a good hard look.

Because it really can change the equation.

7 Comments

Comments are closed.

When discussing ROI, development costs including labor and new applications to create the colorized and personal statements and letters need to be added to the ROI discussions. It will take significant resources to convert pre-printed forms to digital images and to create new colorized statements. All of the data manipulation will come with associated costs. New workflow and CCM software may be needed or at least updated to support the new capabilities of the color inkjet systems. Also consider development costs for a white-paper factory and auto-reprint applications. Both a reality and significant cost savings when implementing CF inkjet technology.

Thanks for the comment Russ. You bring up some great points. Workflow is the great enabler to making production inkjet provide a serious ROI. We endeavor to make sure that there is a project plan that pairs our resources with the customers areas of expertise to deliver a project plan to ensure success.

The transition from warehouse and imprint to a “vitrtual warehouse” (AKA white paper in) is never the same for two customers. There are PSP’s who have customers that see the benefits of being able to put on-page marketing in color and choose to dispose of all inventory immediately, others who have expiring inventory that they would have written off anyway and yet others that choose to burn through remaining inventory before shifting over to a white paper solution. Usually it is the end customer dictating the pace.

What often happens is that PSP’s start out with a mix of each, learn as they go and pace through the journey with their customers at whatever rate works best for both. But often it happens quite quickly because there benefits to PSP and end customer become quite apparent when the entire cost of the legacy process gets compared to the benefits and costs of a production ink jet solution.

Thanks again for the comment.

Russ, You are right, it takes much more work to set up these systems, design the product (brochure, statement, bill, catalog… whatever). Many of us are struggling with this. Static presentation is lower cost and faster to complete and face it, it is still the majority of the work most of us get. However, if the results are like this “Consider CW Niemeyer, ……….The results were dramatic, generating four to five times more revenue than static covers.” I have been working to figure out why many of us are challenged by this opportunity “to charge more for our services and provide better results for our clients”. I worked with Adobe (not for Adobe) for several years and what I saw was that large corporations go to agencies to get help with marketing and these agencies partner with large PSP’s that can generate the personalized products. For those of us that are smaller, we are challenged by our history, this is the way we have done it for years. Our sales teams do not know how to sell these services and the software products we own cannot present and deliver these robust presentations without signification effort. I think we need to consider that our sales and marketing teams need to learn how to sell the value of personalized products. If sales teams and customers are still trying to shave off 1/10th of a penny per piece, then it may be time to re-think how we are communicating with our customers.

I think that overall inkjet ROI is worth it. It does take time, but I think in the long run you do save money and the quality is much better. Thank you for all the helpful information.

Impika can be a solution when they can offer a machine with a print surface 24″x17″ and with a sheet feeder for size 25″x18″ usual we use glossy paper 115gr. I print today only offset but….

always searching manners for a cheap production. Not so simple!! To beat the Price of our production is very dificult!! And i do that with a Heidelberg 1 color from de 80´S

Example: 16,000 brochures (trifoils) Size: 28cmx21.5 in glossy paper 115gr full color both sides is our costumer Price: Q.6,980.00 (US DOLLARS 920.00) Real cost of production is Q.3,500.00

or in us dollar 460.00 after paying my tax 410.00 us dollar clean.

When we make a calculation for production is very clear that one brochure has a cost of US$ 0.0575!! that is not even 6 cents!! The impika do it better? Impika don´t explain prices for the ink like ever!! Tipical like the laser machines with chips! a completly RIPP OFF of the costumer. You need to refill any machine agree but LOW COST!! And the best from a china dealer. It´s one of the reasons that i don´t buy laser or other. It´s a very high inversión and with a short warranty.

we are a small offset bussines starting 3 years ago with nothing!! but….growing fast!

starting with US 2,000.00 and making today arround US 45,000 clean at year and our plan

is to make it doble or triple next year 2016. you can´t believe it? Believe me!! Is a thrue story!!

And we can proof that! Think twice and thousend times before you make a step in that direktion!!

Today the competention is a murder case. And is a hard fight to stay in the market. not so easy then many people thinks!! Trick is: good providers (cheap and fast) low cost production, low cost machinery and hard labor to provide the costumer in time. (Not with a mentality 08h00 at 17h00!!

but a mentality 24 hours 7 days in every week christmas or not!! Because it´s the only way today.

Like a small bussines fighting against the big boys they paying comisions to the buyer (Big companys) especialy her in Guatemala is normal with a full corruption every day.

I am curious that XEROX can do it better. At the moment I don´t think so.

in case they can!! Is more than possible that I am a costumer.

we will see what happen.

Good luck Xerox!!

Henry – thank you for taking the time to comment on this post. Congratulations to your business – it sounds like you are off to a fast and great start. Your growth after 3 years is very impressive – and your mindset is spot-on. Great to see that you have the customer in mind 24/7/365. Cheers to a prosperous future in the industry!