Written by Howard Fenton

Senior Technology Consultant

NAPL

Right before the holidays we were working with a pharmaceutical printer to help them identify and reduce their waste. In this unique niche, waste can be more significant than for general commercial printers because label material and finishing mistakes can be very costly. But truth be told, focusing on paper waste is not a secret or new.

During my tenure with GATF, it was one of the many ways we helped companies reduce their turnaround times and costs associated with waste. That’s why I was so surprised when I stumbled upon an article in PrintWeek called “Trying to measure the immeasurable: substrate management.”

The article is spot on in its introduction when it talks about the cost of paper, how much waste can contribute to the cost of the job and the importance of understanding waste in the estimating process. But then it takes a strange turn and starts talking about a secret conspiracy in the printing and publishing industry that refuses to acknowledge waste in production.

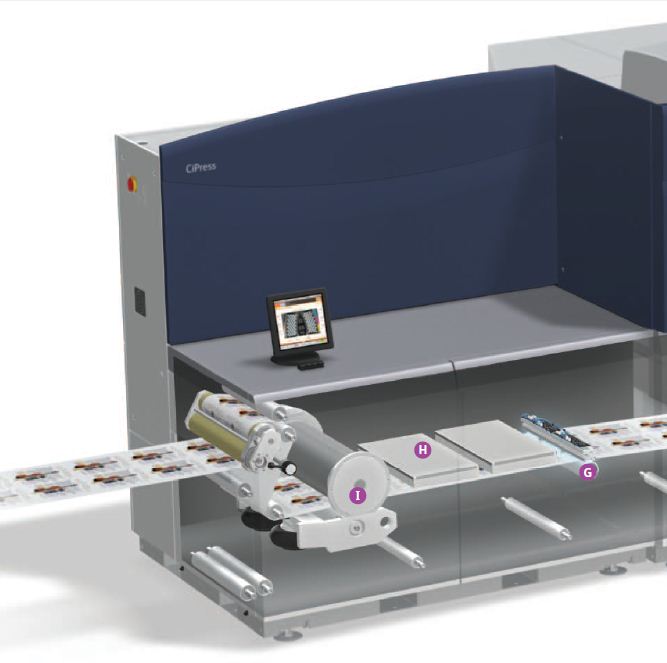

In my experience, leading companies know their cost of manufacturing to the penny. That means they’ve measured the typical waste associated with “printing startups” as well as waste associated with particular presses and finishing options. This is known as anticipated waste, which is different from unanticipated waste. Anticipated waste is factored into the estimate and companies compare actual waste versus anticipated waste as a way to refine the accuracy of estimates.

Paper and other substrate waste is not a secret or mystery. In our audits of production, we often outline strategies to:

- measure waste by bar-coding and weighing the substrates as they enter and exit inventory,

- compare actual versus estimated waste to refine their estimating process, and

- use barcodes to monitor inventory levels and automate reordering and track substrate usage per job, per press, and per operator.

What’s your position on measuring waste? Do you believe in the secret paper waste conspiracy? Or are you a believer in measurement-based performance and measuring your waste?

—

Howard Fenton is a consultant and business advisor at NAPL. Howie advises commercial printers and in-plants on benchmarking performance against industry leaders, increasing productivity through workflow management, adding and integrating new digital services, and adding value through customer research.

I guess measuring waste is the right thing to do to include it in the audit. Businesses focus on saving up to the last penny. This is one measure of success.