Did you read the recent post about the new Xerox inkjet press? It was called “Waterless is Wonderful, At Least in Print” and it referred to the new Xerox Production Color Inkjet System introduced at the Hunkeler Innovationdays on February 15, 2011 in Lucerne, Switzerland. In this deeper dive, we will talk more about inkjet printing.

There are pros and cons of all printing technologies (offset, toner, inkjet) and these advantages can change in an instant when something new and innovative technology is introduced. Fundamentally, inkjet is a simpler technology because it has less moving parts. In most cases it is only the paper that is moving. The simplicity of the system is one reason why inkjets are fast. The new Xerox 4-color digital inkjet press prints CMYK at speeds up to 2,200 pages per minute or 500 feet per minute.

Both toner and inkjet technologies are subject to issues in humidity but in different ways. In toner-based systems, the moisture content of the paper is important in the fusing process while drying and absorption are important in water-based inkjet inks.

But drying and absorption are less of an issue with this new device, because it’s a waterless inkjet technology. This phase change ink technology starts as a solid or in granular form and melts onto the paper and when combined with paper that is slightly heated results in rapid drying. This is why the colors are vivid and why less expensive and lower weight papers can be used without this image show-through.

In contrast with the water-based inks used in other inkjet presses, there is an issue of bleed, which means you can see the color [it shows through] from the other side of the paper. To overcome this issue often more expensive and specially-treated papers are required.

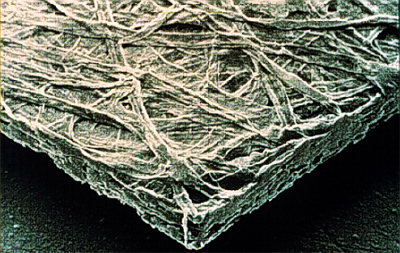

This is the reason that so many ink jet papers have one sort of coating or another. A close-up view(shown above) of a sheet of paper shows the story. Paper is generally a mat of wood fibers with lots of nooks and crannies for water, or any other low viscosity material to travel around in. A drop of water-based ink put one place will flow through the channels giving poorly defined features.

Traditionally inkjet is used in specific niches such as direct mail, transpromo, and most recently short run books. But as we mentioned earlier, innovative changes in technology can shift the pros and cons of different technologies, shift an application from one technology to another and open new and different markets. What do you think? Have you seen the samples from the Xerox waterless inkjet technology? What would you do with it?

Howard Fenton is a Senior Consultant at NAPL. Howie advises commercial printers, in-plants, and manufacturers on workflow management, operations, digital services, and customer research.

I feel that there has always been a trade off in terms of price and quality with inkjet printers. As digital printing becomes more commonplace, people are demanding a better quality of print. Waterless inkjet tech may be able to address this trade off.

Howie, thanks for the info. It will be interesting to learn more as Xerox rolls out this product.

Xerox’s approach and innovation yet again exemplifies that ink jet is in its infancy and future technology will continue to move quality and cost more toward offset.

Inkjet has to inherent advantages over toner that are game changers and will drive innovation: The ability to vary the size of a dot, which has the capability of producing very high quality output.

Secondly, continued speed enhancements. Inkjet is limited only by the ability of the inkjet head to spray onto the substrate.

Toner based technology is limited by physics in transferring the latent image to a photo receptor device.

Last but not least, operational cost of toner versus inkjet. Despite a few arguments I have encountered, putting toner on top of toner to produce a color image is expensive in terms of coverage.

Everyone has to admit ….. Inkjet has expanded beyond the office.